Product Description

Product Description:

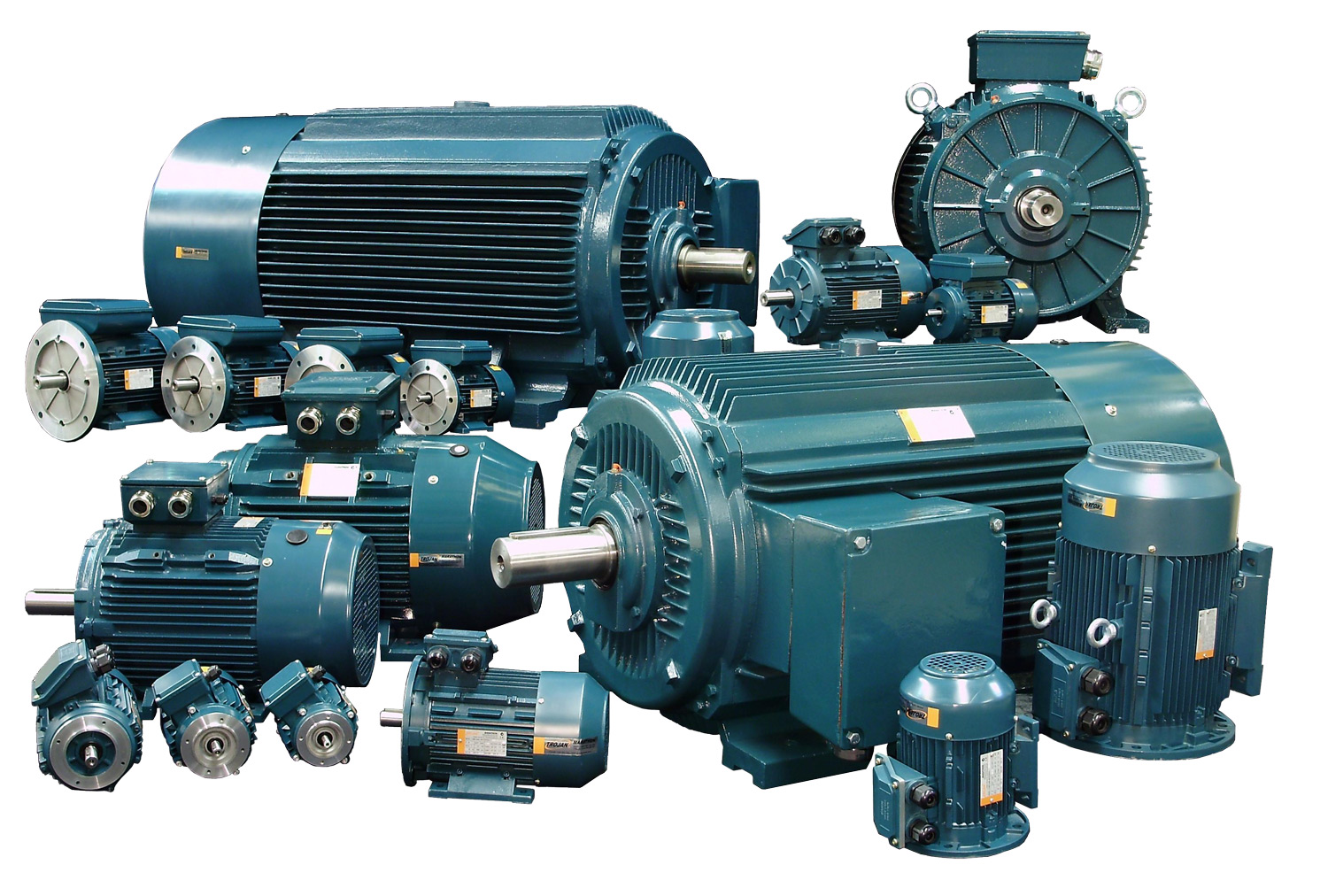

H series permanent magnet synchronous motor is a high efficiency and energy saving motor independently developed and produced by Hui Xunjun. It uses permanent magnet material to generate magnetic field, which has high efficiency, reliable operation, small size, light weight, energy saving and environmental protection, and low noise. It can be matched with servo drive, and realize precise walking and reversing through cooperative motion between servo drive and servo drive, realizing fast response, high stability and high precision control in the whole motion control process. According to the customer’s own characteristics can quickly provide professional customized services. Widely used in machine tools, textile, rewinding, air compressor, fan pump and other industries.

Name plate:

180 series specifications:

Product Feature:

Technical Specification:

Scope of application:

DIMENSION:(UNIT:MM)

Factory outline:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 4 |

| Starting Mode: | Direct on-line Starting |

| Certification: | ISO9001 |

| Customization: |

Available

|

|

|---|

How do electric motors contribute to the efficiency of tasks like transportation?

Electric motors play a significant role in enhancing the efficiency of various transportation tasks. Their unique characteristics and advantages contribute to improved performance, reduced energy consumption, and environmental benefits. Here’s a detailed explanation of how electric motors contribute to the efficiency of tasks like transportation:

- High Energy Conversion Efficiency: Electric motors are known for their high energy conversion efficiency. They can convert a large percentage of electrical energy supplied to them into mechanical energy, resulting in minimal energy losses. Compared to internal combustion engines (ICEs), electric motors can achieve significantly higher efficiencies, which translates to improved energy utilization and reduced fuel consumption.

- Instant Torque and Responsive Performance: Electric motors deliver instant torque, providing quick acceleration and responsive performance. This characteristic is particularly advantageous in transportation tasks, such as electric vehicles (EVs) and electric trains, where rapid acceleration and deceleration are required. The immediate response of electric motors enhances overall vehicle efficiency and driver experience.

- Regenerative Braking: Electric motors enable regenerative braking, a process where the motor acts as a generator to convert kinetic energy into electrical energy during deceleration or braking. This recovered energy is then stored in batteries or fed back into the power grid, reducing energy waste and extending the vehicle’s range. Regenerative braking improves overall efficiency and helps maximize the energy efficiency of electric vehicles.

- Efficient Power Distribution: Electric motors in transportation systems can be powered by electricity generated from various sources, including renewable energy. This allows for a diversified and cleaner energy mix, contributing to reduced greenhouse gas emissions and environmental impact. By utilizing electric motors, transportation tasks can leverage the increasing availability of renewable energy resources, leading to a more sustainable and efficient transport ecosystem.

- Reduced Maintenance Requirements: Electric motors have fewer moving parts compared to ICEs, resulting in reduced maintenance requirements. They eliminate the need for components like spark plugs, fuel injection systems, and complex exhaust systems. As a result, electric motors typically have longer service intervals, lower maintenance costs, and reduced downtime. This enhances operational efficiency and reduces the overall maintenance burden in transportation applications.

- Quiet and Vibration-Free Operation: Electric motors operate quietly and produce minimal vibrations compared to ICEs. This characteristic contributes to a more comfortable and pleasant passenger experience, especially in electric vehicles and electric trains. The reduced noise and vibration levels enhance the overall efficiency and comfort of transportation tasks while minimizing noise pollution in urban environments.

- Efficient Power Management and Control: Electric motors can be integrated with advanced power management and control systems. This allows for precise control over motor speed, torque, and power output, optimizing efficiency for specific transportation tasks. Intelligent control algorithms and energy management systems can further enhance the efficiency of electric motors by dynamically adjusting power delivery based on demand, driving conditions, and energy availability.

- Reduction of Emissions and Environmental Impact: Electric motors contribute to significant reductions in emissions and environmental impact compared to traditional combustion engines. By eliminating direct emissions at the point of use, electric motors help improve air quality and reduce greenhouse gas emissions. When powered by renewable energy sources, electric motors enable nearly zero-emission transportation, paving the way for a cleaner and more sustainable transportation sector.

Through their high energy conversion efficiency, instant torque, regenerative braking, efficient power distribution, reduced maintenance requirements, quiet operation, efficient power management, and environmental benefits, electric motors significantly enhance the efficiency of tasks like transportation. The widespread adoption of electric motors in transportation systems has the potential to revolutionize the industry, promoting energy efficiency, reducing reliance on fossil fuels, and mitigating environmental impact.

What advancements in electric motor technology have improved energy efficiency?

Advancements in electric motor technology have played a crucial role in improving energy efficiency, leading to more sustainable and environmentally friendly applications. Here’s a detailed explanation of some key advancements in electric motor technology that have contributed to enhanced energy efficiency:

- High-Efficiency Motor Designs: One significant advancement in electric motor technology is the development of high-efficiency motor designs. These designs focus on reducing energy losses during motor operation, resulting in improved overall efficiency. High-efficiency motors are engineered with optimized stator and rotor geometries, reduced core losses, and improved magnetic materials. These design enhancements minimize energy wastage and increase the motor’s efficiency, allowing it to convert a higher percentage of electrical input power into useful mechanical output power.

- Premium Efficiency Standards: Another notable advancement is the establishment and adoption of premium efficiency standards for electric motors. These standards, such as the International Electrotechnical Commission (IEC) IE3 and NEMA Premium efficiency standards, set minimum efficiency requirements for motors. Manufacturers strive to meet or exceed these standards by incorporating innovative technologies and design features that enhance energy efficiency. The implementation of premium efficiency standards has led to the widespread availability of more efficient motors in the market, encouraging energy-conscious choices and reducing energy consumption in various applications.

- Variable Speed Drives: Electric motor systems often operate under varying load conditions, and traditional motor designs operate at a fixed speed. However, the development and adoption of variable speed drives (VSDs) have revolutionized motor efficiency. VSDs, such as frequency converters or inverters, allow the motor’s speed to be adjusted according to the load requirements. By operating motors at the optimal speed for each task, VSDs minimize energy losses and significantly improve energy efficiency. This technology is particularly beneficial in applications with variable loads, such as HVAC systems, pumps, and conveyors.

- Improved Motor Control and Control Algorithms: Advanced motor control techniques and algorithms have contributed to improved energy efficiency. These control systems employ sophisticated algorithms to optimize motor performance, including speed control, torque control, and power factor correction. By precisely adjusting motor parameters based on real-time operating conditions, these control systems minimize energy losses and maximize motor efficiency. Additionally, the integration of sensor technology and feedback loops enables closed-loop control, allowing motors to respond dynamically and adaptively to changes in load demand, further enhancing energy efficiency.

- Use of Permanent Magnet Motors: Permanent magnet (PM) motors have gained popularity due to their inherent high energy efficiency. PM motors utilize permanent magnets in the rotor, eliminating the need for rotor windings and reducing rotor losses. This design enables PM motors to achieve higher power densities, improved efficiency, and enhanced performance compared to traditional induction motors. The use of PM motors is particularly prevalent in applications where high efficiency and compact size are critical, such as electric vehicles, appliances, and industrial machinery.

- Integration of Advanced Materials: Advances in materials science have contributed to improved motor efficiency. The utilization of advanced magnetic materials, such as rare-earth magnets, allows for stronger and more efficient magnetic fields, resulting in higher motor efficiency. Additionally, the development of low-loss electrical steel laminations and improved insulation materials reduces core losses and minimizes energy wastage. These advanced materials enhance the overall efficiency of electric motors, making them more energy-efficient and environmentally friendly.

The advancements in electric motor technology, including high-efficiency motor designs, premium efficiency standards, variable speed drives, improved motor control, permanent magnet motors, and advanced materials, have collectively driven significant improvements in energy efficiency. These advancements have led to more efficient motor systems, reduced energy consumption, and increased sustainability across a wide range of applications, including industrial machinery, transportation, HVAC systems, appliances, and renewable energy systems.

How do electric motors generate motion and mechanical work?

Electric motors generate motion and mechanical work through the interaction of magnetic fields and the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors accomplish this:

- Magnetic Fields: Electric motors consist of a stationary part called the stator and a rotating part called the rotor. The stator contains coils of wire that are supplied with an electric current, creating a magnetic field around them. The rotor, on the other hand, typically has magnets or electromagnets that produce their own magnetic fields.

- Magnetic Field Interaction: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor creates a rotational force, also known as torque. This torque causes the rotor to start rotating.

- Electromagnetic Induction: In certain types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current (AC) is supplied to the stator, it creates a changing magnetic field. This changing magnetic field induces voltage in the rotor, which leads to the flow of current in the rotor. The current in the rotor produces its own magnetic field, and the interaction between the stator’s magnetic field and the rotor’s magnetic field results in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, commutation is employed. Commutation is the process of reversing the direction of current in the rotor’s electromagnets as the rotor rotates. This is done using a component called a commutator, which ensures that the magnetic fields of the rotor and the stator are always properly aligned. By periodically reversing the current, the commutator allows for continuous rotation.

- Conversion of Electrical Energy to Mechanical Energy: As the rotor rotates, the mechanical energy is produced. The rotational motion of the rotor is transferred to the motor’s output shaft, which is connected to the load or the device that needs to be driven. The mechanical work is performed as the output shaft drives the load, such as spinning a fan blade, rotating a conveyor belt, or powering a machine.

In summary, electric motors generate motion and mechanical work by utilizing the interaction of magnetic fields and the conversion of electrical energy into mechanical energy. The electric current flowing through the stator’s coils creates a magnetic field that interacts with the magnetic field of the rotor, producing torque and initiating rotation. In some motors, electromagnetic induction is employed, where a changing magnetic field induces voltage and current in the rotor, leading to rotation. Commutation, in certain motor types, ensures continuous rotation by reversing the current in the rotor’s electromagnets. The resulting rotational motion is then transferred to the motor’s output shaft, enabling the motor to perform mechanical work by driving the load.

editor by CX 2024-05-16

China Good quality Senka Oil Change to Electric 48V 60V 72V 2000W 3000W Drive Kit Motor Rear Axle Controller DC Motor vacuum pump adapter

Product Description

| Voltage | 48V/60V | 60V | 48V/60V/72V | 48V/60V/72V | 48V/60V/72V |

| Power | 1000W | 1500W | 1500W | 2000W | 2000W |

| Rated speed | 3000rpm | 3000rpm | 3300rpm | 3300 | 3300 |

| Rated current | 22A | 22A | 22A | 22A | 22A |

| Insulation class | B | B | F | B | B |

| Ourgoing cable length | 1M | 1M | 1M | 1M | 1M |

| N.W | 4.86KG | 4.86KG | 7.3KG | 4.86KG | 10KG |

| Size | 25*16*16cm | 25*16*16cm | 25*16*16cm | 25*16*16cm | 25*16*16cm |

HangZhou Senka Locomotive. Is 1 of the fast-developing tricycle manufacturers in China, which was located in HangZhou City ZheJiang Province, and specialized in research, manufacture and international sales of motor tricycles, cargo tricycle, electric mini car. Our company occupies 6520 square CHINAMFG and has 85 staff members. We have professional R&D team, and we can provide different shape & size of passenger tricycle, cargo tricycle, electric car. We have been accredited to ISO9001: 2008, and product quality well meets CCC national compulsive certification. And our annual production capability achieves 30000 sets. Via 6-year professional export experience, we have built a broad marketing channel, a CHINAMFG customer foundation. At present our main markets are Africa, Southeast Asia, South America and Middle East. “Good Quality, Reasonable Price, Best Service” is our goal. We warmly and sincerely welcome customers all over the world to visit our factory and look CHINAMFG to establishing long term cooperation and CHINAMFG relationship to make mutual benefit. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Car |

|---|---|

| Operating Speed: | Low Speed |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Structure and Working Principle: | Brush |

| OEM: | Yes |

| Customization: |

Available

|

|

|---|

What maintenance practices are essential for prolonging the lifespan of an electric motor?

Maintaining electric motors is crucial for prolonging their lifespan and ensuring optimal performance. Proper maintenance practices help prevent failures, minimize downtime, and maximize the efficiency and reliability of electric motors. Here’s a detailed explanation of essential maintenance practices for prolonging the lifespan of an electric motor:

- Regular Inspections: Conduct regular visual inspections of the motor to identify any signs of wear, damage, or loose connections. Inspect the motor’s external components, such as the housing, bearings, cooling fans, and cables. Look for any unusual noise, vibration, or overheating during operation, as these can indicate potential issues that require attention.

- Lubrication: Proper lubrication is vital for the smooth operation and longevity of electric motors. Follow the manufacturer’s guidelines for lubrication intervals and use the recommended lubricants. Apply lubrication to bearings, shafts, and other moving parts as specified. Over-lubrication or using incompatible lubricants can cause overheating and premature wear, so it’s essential to follow the recommended practices.

- Cleaning: Keep the motor clean and free from dirt, dust, and debris that can accumulate over time. Regularly clean the motor’s exterior using a soft brush or compressed air. Ensure that cooling vents and fans are clear of any obstructions to maintain proper airflow and prevent overheating. Cleanliness helps prevent insulation damage and improves heat dissipation.

- Alignment and Balance: Misalignment or imbalance in the motor’s shaft and coupling can lead to excessive vibrations and premature wear. Regularly check and correct any misalignment or imbalance issues using precision alignment tools. Proper alignment and balance reduce stress on bearings and extend their lifespan, contributing to the overall longevity of the motor.

- Temperature Monitoring: Monitor the motor’s temperature during operation using temperature sensors or thermal imaging techniques. Excessive heat can damage insulation, bearings, and other components. If the motor consistently operates at high temperatures, investigate the cause and take corrective actions, such as improving ventilation, reducing loads, or addressing any cooling system issues.

- Electrical Connections: Inspect and tighten electrical connections regularly to ensure secure and reliable connections. Loose or corroded connections can lead to voltage drops, increased resistance, and overheating. Check terminal blocks, wiring, and motor leads for any signs of damage or degradation. Properly torquing electrical connections and addressing any issues promptly helps maintain electrical integrity.

- Vibration Analysis: Perform regular vibration analysis to detect any abnormal vibration patterns that could indicate underlying issues. Vibration analysis tools and techniques can help identify unbalanced rotors, misalignment, bearing wear, or other mechanical problems. Addressing vibration issues early can prevent further damage and improve motor performance and longevity.

- Periodic Testing and Maintenance: Conduct periodic testing and maintenance based on the manufacturer’s recommendations and industry best practices. This may include insulation resistance testing, winding resistance testing, bearing lubrication checks, and other diagnostic tests. Such tests help identify potential problems before they escalate and allow for timely maintenance and repairs.

- Training and Documentation: Ensure that maintenance personnel are properly trained in electric motor maintenance practices. Provide training on inspection techniques, lubrication procedures, alignment methods, and other essential maintenance tasks. Maintain comprehensive documentation of maintenance activities, including inspection reports, maintenance schedules, and repair records.

By implementing these maintenance practices, motor owners can significantly prolong the lifespan of electric motors. Regular inspections, proper lubrication, cleaning, alignment, temperature monitoring, electrical connection maintenance, vibration analysis, periodic testing, and training contribute to the motor’s reliability, efficiency, and overall longevity.

Are there any emerging trends in electric motor technology, such as smart features?

Yes, there are several emerging trends in electric motor technology, including the integration of smart features. These trends aim to improve motor performance, efficiency, and functionality, while also enabling connectivity and advanced control capabilities. Here’s a detailed explanation of some of the emerging trends in electric motor technology:

- Internet of Things (IoT) Integration: Electric motors are becoming increasingly connected as part of the broader IoT ecosystem. IoT integration allows motors to communicate, share data, and be remotely monitored and controlled. By embedding sensors, communication modules, and data analytics capabilities, motors can provide real-time performance data, predictive maintenance insights, and energy consumption information. This connectivity enables proactive maintenance, optimized performance, and enhanced energy efficiency.

- Condition Monitoring and Predictive Maintenance: Smart electric motors are equipped with sensors that monitor various parameters such as temperature, vibration, and current. This data is analyzed in real-time to detect anomalies and potential faults. By implementing predictive maintenance algorithms, motor failures can be anticipated, enabling maintenance activities to be scheduled proactively. This trend reduces unplanned downtime, improves reliability, and optimizes maintenance costs.

- Advanced Motor Control and Optimization: Emerging electric motor technologies focus on advanced motor control techniques and optimization algorithms. These advancements allow for precise control of motor performance, adapting to changing load conditions, and optimizing energy efficiency. Additionally, sophisticated control algorithms enable motor systems to operate in coordination with other equipment, such as variable speed drives, power electronics, and energy storage systems, resulting in improved overall system efficiency.

- Energy Harvesting and Regenerative Features: Electric motors can harness energy through regenerative braking and energy harvesting techniques. Regenerative braking allows motors to recover and convert kinetic energy into electrical energy, which can be fed back into the system or stored for later use. Energy harvesting technologies, such as piezoelectric or electromagnetic systems, can capture ambient energy and convert it into usable electrical energy. These features enhance energy efficiency and reduce overall power consumption.

- Integration with Artificial Intelligence (AI) and Machine Learning (ML): The integration of electric motors with AI and ML technologies enables advanced motor control, optimization, and decision-making capabilities. AI and ML algorithms analyze motor performance data, identify patterns, and make real-time adjustments to optimize efficiency and performance. The combination of AI/ML with electric motors opens up possibilities for autonomous motor control, adaptive energy management, and intelligent fault detection.

- Miniaturization and Lightweight Design: Emerging trends in electric motor technology focus on miniaturization and lightweight design without compromising performance. This trend is particularly relevant for portable devices, electric vehicles, and aerospace applications. Advancements in materials, manufacturing processes, and motor design allow for smaller, lighter, and more powerful motors, enabling greater mobility, improved efficiency, and increased power density.

The integration of smart features in electric motor technology is driving advancements in connectivity, data analytics, predictive maintenance, advanced control, energy harvesting, AI/ML integration, and miniaturization. These trends are revolutionizing the capabilities and functionality of electric motors, making them more intelligent, efficient, and adaptable to various applications. As technology continues to evolve, electric motors are expected to play a crucial role in the ongoing transition towards smart and sustainable industries.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2024-05-15

China manufacturer DC Gearless Brushless Encoder Delivery Robot Drive Electric Wheel Hub Servo Motor with CE with Good quality

Product Description

Product Description

HangZhou K-Easy Automation Co.,Limited is a professional manufacturer, specialize in R&D And production of AC drives. We have built up a comprehensive product family. Frequency inverters’ power covers the range from 0.4 to 630kW, and voltage range is between 220V and 480V. More than inverters are running smoothly 300, 000 units at different industrial sites.

-

The response frequency is up to 1.5KHz, which is especially suitable for applications requiring high-speed response;

-

Driver menu, control interface, parameter modification and writing operation are consistent with CHINAMFG A5 series servo driver;

-

The encoder interface of A-type servo driver is consistent with CHINAMFG A5 series servo driver, and it can directly operate with CHINAMFG A5 and A6 servo motors;

-

The driver can directly drive the direct drive motor, and can support up to 23 bit absolute encoder;

-

It is provided with electronic cam special machine and internal position special machine;

-

The driver is currently used in automation equipment such as manipulator, loading and unloading, winding machine, die-cutting machine, 3C processing, fine carving, textile, SCARA robot, tensile machine, capping machine, labeling machine, etc.

Product Parameters

| Performance | K-Drive |

|---|---|

| Applicable motors | Asynchronous /synchronous motors |

| Starting torque | 0.5Hz, 180% (sensor-less vector control) 0Hz, 200% (closed-loop vector control) |

| Speed adjustable range | 1:200 (SVC), 1:1000 (VC) |

| Ambient temperature (no derating required) | -10-50ºC (for most of the models) |

| Rated input voltage | 208VAC-480VAC |

| Communication | Modbus RTU//ASCII Profibus-DP, CANopen, etc. |

| Position control (fixed length, or angular positioning) | √ |

| Field weakening control | √ |

| Autotune online | Online & Offline |

| Short-time ramp-up | No trip |

| Customized features (software and/or hardware) | Procurable with rich experience |

Product Features

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | High-performance Transducer, Three Phase Transducer, General Transducer, Single-phase Transducer, High Frequency Converter Transducer |

|---|---|

| Output Type: | Triple |

| Principle of Work: | Vector Control Transducer |

| Switch Mode: | High Carrier Frequency PWM Control |

| Main Circuit Type: | Voltage |

| Voltage of Power Supply: | Low Voltage Variable-Frequency Drive |

| Samples: |

US$ 78/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do manufacturers ensure the quality and reliability of electric motors?

Manufacturers employ several measures and quality control processes to ensure the quality and reliability of electric motors. These measures span from design and manufacturing stages to testing and inspections. Here’s a detailed explanation of how manufacturers ensure the quality and reliability of electric motors:

- Robust Design and Engineering: Manufacturers invest significant effort in designing electric motors with robust engineering principles. This involves careful selection of materials, precise calculations, and simulation techniques to ensure optimal performance and durability. Thorough design reviews and analysis are conducted to identify potential issues and optimize the motor’s design for reliability.

- Stringent Manufacturing Processes: Manufacturers adhere to stringent manufacturing processes to maintain consistent quality standards. This includes using advanced manufacturing technologies, automated assembly lines, and precision machining to ensure accurate and reliable motor production. Strict quality control measures are implemented at each stage of manufacturing, including material inspection, component testing, and assembly verification.

- Quality Control and Testing: Comprehensive quality control and testing procedures are implemented to assess the performance and reliability of electric motors. This includes electrical testing to verify motor characteristics such as voltage, current, power consumption, and efficiency. Mechanical testing is conducted to assess factors like torque, vibration, and noise levels. Additionally, endurance tests are performed to evaluate the motor’s performance over extended operating periods.

- Certifications and Compliance: Electric motor manufacturers often obtain certifications and comply with industry standards to ensure quality and reliability. These certifications, such as ISO 9001, IEC standards, and UL certifications, demonstrate that the manufacturer follows recognized quality management systems and meets specific requirements for product safety, performance, and reliability. Compliance with these standards provides assurance to customers regarding the motor’s quality.

- Reliability Testing: Manufacturers conduct extensive reliability testing to assess the motor’s performance under various conditions and stress factors. This may include accelerated life testing, temperature and humidity testing, thermal cycling, and load testing. Reliability testing helps identify potential weaknesses, evaluate the motor’s robustness, and ensure it can withstand real-world operating conditions without compromising performance or reliability.

- Continuous Improvement and Feedback: Manufacturers emphasize continuous improvement by gathering feedback from customers, field testing, and warranty analysis. By monitoring the performance of motors in real-world applications, manufacturers can identify any issues or failure patterns and make necessary design or process improvements. Customer feedback also plays a crucial role in driving improvements and addressing specific requirements.

- Quality Assurance and Documentation: Manufacturers maintain comprehensive documentation throughout the production process to ensure traceability and quality assurance. This includes recording and tracking raw materials, components, manufacturing parameters, inspections, and testing results. Proper documentation allows manufacturers to identify any deviations, track the motor’s history, and enable effective quality control and post-production analysis.

- Supplier Evaluation and Control: Manufacturers carefully evaluate and select reliable suppliers for motor components and materials. Supplier quality control processes are established to ensure that the sourced components meet the required specifications and quality standards. Regular supplier audits, inspections, and quality assessments are conducted to maintain a consistent supply chain and ensure the overall quality and reliability of the motors.

By implementing these measures, manufacturers ensure the quality and reliability of electric motors. Through robust design, stringent manufacturing processes, comprehensive testing, compliance with standards, continuous improvement, and effective quality control, manufacturers strive to deliver electric motors that meet or exceed customer expectations for performance, durability, and reliability.

How do electric motors contribute to the precision of tasks like robotics?

Electric motors play a critical role in enabling the precision of tasks in robotics. Their unique characteristics and capabilities make them well-suited for precise and controlled movements required in robotic applications. Here’s a detailed explanation of how electric motors contribute to the precision of tasks in robotics:

- Precise Positioning: Electric motors offer precise positioning capabilities, allowing robots to move with accuracy and repeatability. By controlling the motor’s speed, direction, and rotation, robots can achieve precise position control, enabling them to perform tasks with high levels of accuracy. This is particularly important in applications that require precise manipulation, such as assembly tasks, pick-and-place operations, and surgical procedures.

- Speed Control: Electric motors provide precise speed control, allowing robots to perform tasks at varying speeds depending on the requirements. By adjusting the motor’s speed, robots can achieve smooth and controlled movements, which is crucial for tasks that involve delicate handling or interactions with objects or humans. The ability to control motor speed precisely enhances the overall precision and safety of robotic operations.

- Torque Control: Electric motors offer precise torque control, which is essential for tasks that require forceful or delicate interactions. Torque control allows robots to exert the appropriate amount of force or torque, enabling them to handle objects, perform assembly tasks, or execute movements with the required precision. By modulating the motor’s torque output, robots can delicately manipulate objects without causing damage or apply sufficient force for tasks that demand strength.

- Feedback Control Systems: Electric motors in robotics are often integrated with feedback control systems to enhance precision. These systems utilize sensors, such as encoders or resolvers, to provide real-time feedback on the motor’s position, speed, and torque. The feedback information is used to continuously adjust and fine-tune the motor’s performance, compensating for any errors or deviations and ensuring precise movements. The closed-loop nature of feedback control systems allows robots to maintain accuracy and adapt to dynamic environments or changing task requirements.

- Dynamic Response: Electric motors exhibit excellent dynamic response characteristics, enabling quick and precise adjustments to changes in command signals. This responsiveness is particularly advantageous in robotics, where rapid and accurate movements are often required. Electric motors can swiftly accelerate, decelerate, and change direction, allowing robots to perform intricate tasks with precision and efficiency.

- Compact and Lightweight: Electric motors are available in compact and lightweight designs, making them suitable for integration into various robotic systems. Their small size and high power-to-weight ratio allow for efficient utilization of space and minimal impact on the overall weight and size of the robot. This compactness and lightness contribute to the overall precision and maneuverability of robotic platforms.

Electric motors, with their precise positioning, speed control, torque control, feedback control systems, dynamic response, and compactness, significantly contribute to the precision of tasks in robotics. These motors enable robots to execute precise movements, manipulate objects with accuracy, and perform tasks that require high levels of precision. The integration of electric motors with advanced control algorithms and sensory feedback systems empowers robots to adapt to various environments, interact safely with humans, and achieve precise and controlled outcomes in a wide range of robotic applications.

How do electric motors handle variations in load, speed, and torque?

Electric motors are designed to handle variations in load, speed, and torque through various control mechanisms and techniques. Here’s a detailed explanation of how electric motors handle these variations:

- Load Variations: Electric motors can handle variations in load by adjusting the amount of torque they produce. When the load on the motor increases, such as when additional resistance or weight is applied, the motor responds by increasing the torque output. This is achieved through the control of the motor’s input current or voltage. For example, in DC motors, increasing the current supplied to the motor can compensate for the increased load, ensuring that the motor can continue to operate at the desired speed.

- Speed Variations: Electric motors can handle variations in speed by adjusting the frequency of the power supply or by varying the voltage applied to the motor. In AC motors, the speed is determined by the frequency of the alternating current, so changing the frequency can alter the motor’s speed. In DC motors, the speed can be controlled by adjusting the voltage applied to the motor. This can be achieved using electronic speed controllers (ESCs) or by employing pulse width modulation (PWM) techniques to control the average voltage supplied to the motor.

- Torque Variations: Electric motors can handle variations in torque by adjusting the current flowing through the motor windings. The torque produced by a motor is directly proportional to the current flowing through the motor. By increasing or decreasing the current, the motor can adjust its torque output to match the requirements of the load. This can be accomplished through various control methods, such as using motor drives or controllers that regulate the current supplied to the motor based on the desired torque.

- Control Systems: Electric motors often incorporate control systems to handle variations in load, speed, and torque more precisely. These control systems can include feedback mechanisms, such as encoders or sensors, which provide information about the motor’s actual speed or position. The feedback signals are compared to the desired speed or position, and the control system adjusts the motor’s input parameters accordingly to maintain the desired performance. This closed-loop control allows electric motors to respond dynamically to changes in load, speed, and torque.

In summary, electric motors handle variations in load, speed, and torque through various control mechanisms. By adjusting the current, voltage, or frequency of the power supply, electric motors can accommodate changes in load and speed requirements. Additionally, control systems with feedback mechanisms enable precise regulation of motor performance, allowing the motor to respond dynamically to variations in load, speed, and torque. These control techniques ensure that electric motors can operate effectively across a range of operating conditions and adapt to the changing demands of the application.

editor by CX 2024-05-14

China supplier 22kw Ye2 Series Pump Drive Three-Phase AC Electric Induction Asynchronous Motor with Good quality

Product Description

Product Description

Features: High efficiency and energy saving, low noise and little vibration. Insulation class: F;Protection class:IP54 or IP55.

General purpose including cutting machines, pumps, fans, conveyors, machines tools of farm duty and food process.

The altitude not exceeding 1000m above sea level. The ambient temperature subject to seasonal variations but no exceeding+40ºC and not less than-15ºC.

Company Profile

ZheJiang Lanyoung Electromechanical Co., Ltd was originated from 1988, established in 2001, it owns ZheJiang Lanyoung Electromechanical Co., Ltd HangZhouShan City Branch and ZHangZhoug HangZhouang Electromechanical Co., Ltd, won the honorary title of “top 10 brands of brand network in 2019” and “excellent demonstration unit of ZHangZhoug focusing on quality and brand-making”. We are a modern company combining mechanical and electrical products research, development, production, sales and service with a long history and rich experience in production. We are experts of water pumps, motors, and fans products, the main products are stainless steel pumps, plastic corrosion-resistant submersible pumps, DC electric pumps, self-priming pump, machine tool cooling pumps, corrosion resistant pumps, sewage pumps, oil-immersed submersible pumps, blowers, medium pressure fan, multi-wing fan and so on, and we also possess practical new-type patent for a mini submersible pump. The above products can be all customized according to customer’s requirement. We have special advantages that is different from other manufacturing companies.

Product Parameters

| Type | Power | Pole/Speed | Volt/Frequency | Insulation | Protection | Motor housing | Mount |

| kw /HP | |||||||

| 80M2 | 0.55/0.75 | 6/885rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 90S | 0.75/1 | 6/910rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 90L | 1.1/1.5 | 6/910rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 100L | 1.5/2 | 6/940rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 112M | 2.2/3 | 6/940rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132S | 3/4 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132M1 | 4/5.5 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 132M2 | 5.5/7.5 | 6/960rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 160M | 7.5/10 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 160L | 11/15 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 180L | 15/20 | 6/970rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 200L1 | 18.5/25 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 200L2 | 22/30 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 225M | 30/40 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 250M | 37/50 | 6/980rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 280S | 45/60 | 6/985rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 280M | 55/75 | 6/985rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

| 315S | 75/100 | 6/990rpm | 380V/50HZ | class F | IP55 | Cast Iron | B3 |

Detailed Photos

Packaging & Shipping

Certifications

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial |

|---|---|

| Operating Speed: | Constant Speed |

| Number of Stator: | Three-Phase |

| Samples: |

US$ 29/Piece

1 Piece(Min.Order) | Order Sample Blue

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What factors should be considered when selecting the right electric motor for a task?

When selecting the right electric motor for a task, several factors need to be considered to ensure optimal performance and compatibility. Here’s a detailed overview of the factors that should be taken into account:

- Load Requirements: The first consideration is understanding the specific load requirements of the task. This includes factors such as the torque or force needed to drive the load, the speed range required, and any variations in load that may occur. By accurately assessing the load requirements, you can determine the appropriate motor type, size, and characteristics needed to handle the task effectively.

- Motor Type: Different motor types are suited for specific applications. Common motor types include AC induction motors, brushless DC motors, brushed DC motors, and stepper motors. Each type has its own advantages and limitations in terms of speed range, torque characteristics, efficiency, control requirements, and cost. Choosing the right motor type depends on the task’s specific requirements and the desired performance.

- Power Supply: Consider the available power supply for the motor. Determine whether the application requires AC or DC power and the voltage and frequency range of the power source. Ensure that the motor’s power requirements align with the available power supply to avoid compatibility issues.

- Efficiency and Energy Consumption: Efficiency is an important factor to consider, especially for applications where energy consumption is a concern. Higher motor efficiency translates to lower energy losses and reduced operating costs over the motor’s lifetime. Look for motors with high efficiency ratings to minimize energy consumption and improve overall system efficiency.

- Environmental Factors: Assess the environmental conditions in which the motor will operate. Consider factors such as temperature, humidity, dust, and vibration. Some motors are specifically designed to withstand harsh environmental conditions, while others may require additional protection or enclosures. Choosing a motor that is suitable for the intended environment will ensure reliable and long-lasting operation.

- Control and Feedback Requirements: Determine whether the application requires precise control over motor speed, position, or torque. Some tasks may benefit from closed-loop control systems that incorporate feedback devices like encoders or sensors to provide accurate motor control. Evaluate the control and feedback requirements of the task and select a motor that is compatible with the desired control mechanism.

- Physical Constraints: Consider any physical constraints or limitations that may impact motor selection. These constraints may include space restrictions, weight limitations, mounting options, and mechanical compatibility with other components or equipment. Ensure that the chosen motor can physically fit and integrate into the system without compromising performance or functionality.

- Cost and Budget: Finally, consider the budget and cost constraints associated with the motor selection. Evaluate the initial purchase cost of the motor as well as the long-term operating costs, including maintenance and energy consumption. Strive to strike a balance between performance and cost-effectiveness to ensure the best value for your specific application.

By considering these factors, you can make an informed decision when selecting the right electric motor for a task. It is crucial to thoroughly analyze the requirements and match them with the motor’s specifications to achieve optimal performance, reliability, and efficiency.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

How do electric motors generate motion and mechanical work?

Electric motors generate motion and mechanical work through the interaction of magnetic fields and the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors accomplish this:

- Magnetic Fields: Electric motors consist of a stationary part called the stator and a rotating part called the rotor. The stator contains coils of wire that are supplied with an electric current, creating a magnetic field around them. The rotor, on the other hand, typically has magnets or electromagnets that produce their own magnetic fields.

- Magnetic Field Interaction: When an electric current flows through the coils in the stator, it generates a magnetic field. The interaction between the magnetic fields of the stator and the rotor creates a rotational force, also known as torque. This torque causes the rotor to start rotating.

- Electromagnetic Induction: In certain types of electric motors, such as induction motors, electromagnetic induction plays a significant role. When alternating current (AC) is supplied to the stator, it creates a changing magnetic field. This changing magnetic field induces voltage in the rotor, which leads to the flow of current in the rotor. The current in the rotor produces its own magnetic field, and the interaction between the stator’s magnetic field and the rotor’s magnetic field results in rotation.

- Commutation: In motors that use direct current (DC), such as brushed DC motors, commutation is employed. Commutation is the process of reversing the direction of current in the rotor’s electromagnets as the rotor rotates. This is done using a component called a commutator, which ensures that the magnetic fields of the rotor and the stator are always properly aligned. By periodically reversing the current, the commutator allows for continuous rotation.

- Conversion of Electrical Energy to Mechanical Energy: As the rotor rotates, the mechanical energy is produced. The rotational motion of the rotor is transferred to the motor’s output shaft, which is connected to the load or the device that needs to be driven. The mechanical work is performed as the output shaft drives the load, such as spinning a fan blade, rotating a conveyor belt, or powering a machine.

In summary, electric motors generate motion and mechanical work by utilizing the interaction of magnetic fields and the conversion of electrical energy into mechanical energy. The electric current flowing through the stator’s coils creates a magnetic field that interacts with the magnetic field of the rotor, producing torque and initiating rotation. In some motors, electromagnetic induction is employed, where a changing magnetic field induces voltage and current in the rotor, leading to rotation. Commutation, in certain motor types, ensures continuous rotation by reversing the current in the rotor’s electromagnets. The resulting rotational motion is then transferred to the motor’s output shaft, enabling the motor to perform mechanical work by driving the load.

editor by CX 2024-04-16

China Best Sales ZD Change Drive Torque 72mm Brush/Brushless Precision Planetary Transmission Gear Motor motor brushes

Product Description

ZD Change Drive Torque 72mm Brush/Brushless Precision Planetary Transmission Gear Motor

Detailed Photos

Product Parameters

MODEL:Z72BLDPN24120-30S(72PN3.65)

Other Related Products

Click Here For More Details

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you !

| Application: | Motor, Electric Cars |

|---|---|

| Function: | Change Drive Torque, Speed Changing |

| Layout: | Transmission |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Dynamic Modeling of a Planetary Motor

A planetary gear motor consists of a series of gears rotating in perfect synchrony, allowing them to deliver torque in a higher output capacity than a spur gear motor. Unlike the planetary motor, spur gear motors are simpler to build and cost less, but they are better for applications requiring lower torque output. That is because each gear carries the entire load. The following are some key differences between the two types of gearmotors.

planetary gear system

A planetary gear transmission is a type of gear mechanism that transfers torque from one source to another, usually a rotary motion. Moreover, this type of gear transmission requires dynamic modeling to investigate its durability and reliability. Previous studies included both uncoupled and coupled meshing models for the analysis of planetary gear transmission. The combined model considers both the shaft structural stiffness and the bearing support stiffness. In some applications, the flexible planetary gear may affect the dynamic response of the system.

In a planetary gear device, the axial end surface of the cylindrical portion is rotatable relative to the separating plate. This mechanism retains lubricant. It is also capable of preventing foreign particles from entering the planetary gear system. A planetary gear device is a great choice if your planetary motor’s speed is high. A high-quality planetary gear system can provide a superior performance than conventional systems.

A planetary gear system is a complex mechanism, involving three moving links that are connected to each other through joints. The sun gear acts as an input and the planet gears act as outputs. They rotate about their axes at a ratio determined by the number of teeth on each gear. The sun gear has 24 teeth, while the planet gears have three-quarters that ratio. This ratio makes a planetary motor extremely efficient.

planetary gear train

To predict the free vibration response of a planetary motor gear train, it is essential to develop a mathematical model for the system. Previously, static and dynamic models were used to study the behavior of planetary motor gear trains. In this study, a dynamic model was developed to investigate the effects of key design parameters on the vibratory response. Key parameters for planetary gear transmissions include the structure stiffness and mesh stiffness, and the mass and location of the shaft and bearing supports.

The design of the planetary motor gear train consists of several stages that can run with variable input speeds. The design of the gear train enables the transmission of high torques by dividing the load across multiple planetary gears. In addition, the planetary gear train has multiple teeth which mesh simultaneously in operation. This design also allows for higher efficiency and transmittable torque. Here are some other advantages of planetary motor gear trains. All these advantages make planetary motor gear trains one of the most popular types of planetary motors.

The compact footprint of planetary gears allows for excellent heat dissipation. High speeds and sustained performances will require lubrication. This lubricant can also reduce noise and vibration. But if these characteristics are not desirable for your application, you can choose a different gear type. Alternatively, if you want to maintain high performance, a planetary motor gear train will be the best choice. So, what are the advantages of planetary motor gears?

planetary gear train with fixed carrier train ratio

The planetary gear train is a common type of transmission in various machines. Its main advantages are high efficiency, compactness, large transmission ratio, and power-to-weight ratio. This type of gear train is a combination of spur gears, single-helical gears, and herringbone gears. Herringbone planetary gears have lower axial force and high load carrying capacity. Herringbone planetary gears are commonly used in heavy machinery and transmissions of large vehicles.

To use a planetary gear train with a fixed carrier train ratio, the first and second planets must be in a carrier position. The first planet is rotated so that its teeth mesh with the sun’s. The second planet, however, cannot rotate. It must be in a carrier position so that it can mesh with the sun. This requires a high degree of precision, so the planetary gear train is usually made of multiple sets. A little analysis will simplify this design.

The planetary gear train is made up of three components. The outer ring gear is supported by a ring gear. Each gear is positioned at a specific angle relative to one another. This allows the gears to rotate at a fixed rate while transferring the motion. This design is also popular in bicycles and other small vehicles. If the planetary gear train has several stages, multiple ring gears may be shared. A stationary ring gear is also used in pencil sharpener mechanisms. Planet gears are extended into cylindrical cutters. The ring gear is stationary and the planet gears rotate around a sun axis. In the case of this design, the outer ring gear will have a -3/2 planet gear ratio.

planetary gear train with zero helix angle

The torque distribution in a planetary gear is skewed, and this will drastically reduce the load carrying capacity of a needle bearing, and therefore the life of the bearing. To better understand how this can affect a gear train, we will examine two studies conducted on the load distribution of a planetary gear with a zero helix angle. The first study was done with a highly specialized program from the bearing manufacturer INA/FAG. The red line represents the load distribution along a needle roller in a zero helix gear, while the green line corresponds to the same distribution of loads in a 15 degree helix angle gear.

Another method for determining a gear’s helix angle is to consider the ratio of the sun and planet gears. While the sun gear is normally on the input side, the planet gears are on the output side. The sun gear is stationary. The two gears are in engagement with a ring gear that rotates 45 degrees clockwise. Both gears are attached to pins that support the planet gears. In the figure below, you can see the tangential and axial gear mesh forces on a planetary gear train.

Another method used for calculating power loss in a planetary gear train is the use of an auto transmission. This type of gear provides balanced performance in both power efficiency and load capacity. Despite the complexities, this method provides a more accurate analysis of how the helix angle affects power loss in a planetary gear train. If you’re interested in reducing the power loss of a planetary gear train, read on!

planetary gear train with spur gears

A planetary gearset is a type of mechanical drive system that uses spur gears that move in opposite directions within a plane. Spur gears are one of the more basic types of gears, as they don’t require any specialty cuts or angles to work. Instead, spur gears use a complex tooth shape to determine where the teeth will make contact. This in turn, will determine the amount of power, torque, and speed they can produce.

A two-stage planetary gear train with spur gears is also possible to run at variable input speeds. For such a setup, a mathematical model of the gear train is developed. Simulation of the dynamic behaviour highlights the non-stationary effects, and the results are in good agreement with the experimental data. As the ratio of spur gears to spur gears is not constant, it is called a dedendum.

A planetary gear train with spur gears is a type of epicyclic gear train. In this case, spur gears run between gears that contain both internal and external teeth. The circumferential motion of the spur gears is analogous to the rotation of planets in the solar system. There are four main components of a planetary gear train. The planet gear is positioned inside the sun gear and rotates to transfer motion to the sun gear. The planet gears are mounted on a joint carrier that is connected to the output shaft.

planetary gear train with helical gears

A planetary gear train with helical teeth is an extremely powerful transmission system that can provide high levels of power density. Helical gears are used to increase efficiency by providing a more efficient alternative to conventional worm gears. This type of transmission has the potential to improve the overall performance of a system, and its benefits extend far beyond the power density. But what makes this transmission system so appealing? What are the key factors to consider when designing this type of transmission system?

The most basic planetary train consists of the sun gear, planet gear, and ring gear elements. The number of planets varies, but the basic structure of planetary gears is similar. A simple planetary geartrain has the sun gear driving a carrier assembly. The number of planets can be as low as two or as high as six. A planetary gear train has a low mass inertia and is compact and reliable.

The mesh phase properties of a planetary gear train are particularly important in designing the profiles. Various parameters such as mesh phase difference and tooth profile modifications must be studied in depth in order to fully understand the dynamic characteristics of a PGT. These factors, together with others, determine the helical gears’ performance. It is therefore essential to understand the mesh phase of a planetary gear train to design it effectively.

editor by CX 2023-06-06

China Professional Sk45sr Sk50 Final Drive Excavator E305.5 E304 E305cr E306 Travel Motor for Spare Parts brushless motor

Product Description

SK45SR SK50 Final Drive Excavator E305.5 E304 E305CR E306 Travel Motor For Spare Parts

|

Product Parameter |

|

|

Product |

Travel Gearbox |

|

Part No |

E305.5 E304 E305CR E306 |

|

Warranty |

6-12 Month |

|

Condition |

100% New |

|

MOQ |

1 Piece |

|

Payment |

T/T, Alibaba Trade Assurance, Paypal, etc |

|

Delivery Time |

1-2 working days |

|

Packing |

Wooden box Ex Standard exporting packing |

|

Transport |

By sea/air/express (DHL/FEDEX/TNT/UPS/EMS/City-line) |

Our Travel Gearbox Advantages

1. Completely, assembly, and ready to installed in your excavators.

2. With MOTOR,

3. All components are produced by us.

4. All new, undamaged.

5. Painted or Unpainted, depend on requirement

6. 90 days warranty, call or email with any questions.

7. Plywood Case Packing, free of fumigation

8. Deliver to worldwide by Sea, Air, or Carrier.

Hot Selling Travel Gearbox model

| PC200-7/8 | PC200-7/8 | TRAVEL MOTOR ASSY | |||

| ZAX870-3 | YB60000031 | TRAVEL MOTOR ASSY | |||

| PC120-6E | TRAVEL MOTOR ASSY | ||||

| PC120-6 | PC120-6 | TRAVEL MOTOR ASSY | |||

| KYB | MAG-170VP-3800-10 (B5710-93099) | TRAVEL MOTOR ASSY | |||

| EC210B | 14528732 | TRAVEL MOTOR ASSY | |||

| E330D | E330D FINAL DRIVE ASSY | TRAVEL MOTOR ASSY | |||

| PC40 | 20T657100 | TRAVEL MOTOR ASSY | |||

| KYB | MAG-170VP-G-GT40D43B (B5710-93111) | TRAVEL MOTOR ASSY | |||

| PC120-6 | PC130-7 TRAVEL MOTOR ASSY | TRAVEL MOTOR ASSY | |||

| SOLAR 150LC-V | 401-00034 | TRAVEL MOTOR ASSY | |||

| PC300 PC350 | 207-27-0 0571 | TRAVEL MOTOR ASSY | |||

| R210-7 | 39Q6-41110 | TRAVEL MOTOR ASSY | |||

| E320D | 334-9986 | TRAVEL MOTOR ASSY | |||

| E307 | E307 TRAVEL MOTOR ASSY | TRAVEL MOTOR ASSY | |||

More Travel Gearbox model we can offer

| EXCAVATOR | MODELS | |||||

| CATERPILLA*R | E70 | E70B | E70B-7 | E70C | E120 | E140B |

| E200B | E240 | E240B | E300B | E305 | E311 | |

| E312 | E312B | E312C | E315 | E315B | E315C | |

| E325 | E325B | E330 | E330B | E330C | E340B | |

| E450 | ||||||

| PC SERIES | PC45 | PC50 | PC50-2 | PC50-5 | PC55 | PC90 |

| PC60 | PC60-2 | PC60-3 | PC60-5 | PC60-6 | PC60-7 | |

| PC100 | PC100-3 | PC100-5 | PC100-6 | PC150 | PC150-3 | |

| PC120 | PC120-3 | PC120-5 | PC120-6 | PC150-5 | ||

| PC200-1 | PC200-2 | PC200-3 | PC200-5 | PC200-6 | PC200-7 | |

| PC220-1 | PC220-3 | PC220-5 | PC220-7 | PC75 | PC80 | |

| PC300-3 | PC300-5 | PC300-6 | PC300-7 | |||

| PC400 | PC400-3 | PC400-6 | PC450 | PC450-6 | ||

| HITACHI– | EX60-1 | EX60-2 | EX60-3 | EX60-5 | EX60-6 | EX70 |

| EX100 | EX100-2 | EX80-5 | EX135 | EX160-1 | ||

| EX120 | EX120-2 | EX120-5 | EX120-6 | EX120-7 | ||

| EX200-1 | EX200-2 | EX200-3 | EX200-5 | EX200-6 | EX210-1 | |

| EX220-1 | EX220-2 | EX220-3 | EX220-5 | EX220-6 | EX270 | |

| EX300-1 | EX300-2 | EX300-3 | EX300-5 | EX330 | ||

| EX400 | EX400-3 | EX450 | EX450-5 | EX500-3 | ||

| ZX55 | ZX120 | ZX200 | ZX230 | |||

| UH04 | UH07-5 | UH07-7 | UH160 | KH120-2 | ||

| KATO | HD55 | HD100 | HD140 | HD140-3 | ||

| HD250 | HD250-1 | HD250-2 | HD250G | HD250-7 | ||

| HD300 | HD307 | HD400 | HD400-2 | HD400-5 | HD400-7 | |

| HD450 | HD450-2 | HD450-7 | HD450SE | HD400SEM | ||

| HD550 | HD550-2 | HD550-3 | HD550-5 | HD550-7 | ||

| HD700-2 | HD700-5 | HD700-7 | HD770-1 | HD770-2 | ||

| HD800-1 | HD800-2 | HD800-5 | HD800-7 | HD820 | ||

| HD880-1 | HD880-2 | HD880-5 | HD900-5 | HD900-7 | HD1880-1 | |

| HD1220 | HD1250 | HD1250-5 | HD1250-7 | HD120-7(6D102) | ||

| KOBELCO | SK09 | SK50 | SK55 | SK130 | SK135 | SK160 |

| SK60 | SK60-3 | SK60-6 | SK60-7 | SK70-6 | SK55 | |

| SK100-1 | SK100-3 | SK100-5 | SK120 | SK120-3 | SK120-5 | |

| SK200-1 | SK200-2 | SK200-3 | SK200-5 | SK200-6 | SK200-6E | |

| SK200-7 | SK210-6 | SK220-1 | SK220-3 | SK230 | SK230-6E | |

| SK230-8 | SK260 | SK300 | SK310 | SK310-3 | SK330 | |

| SK330-8 | SK450-1 | |||||

| SUMITOMO | SH30 | SH40 | SH60 | SH75 | SH100 | SH130 |

| SH120 | SH120A1 | SH120-3 | SH120-6 | SH120A3 | ||

| SH200 | SH200A1 | SH200A3 | SH220 | SH260 | SH265 | |

| SH280 | SH280DJ | SH280EJ | SH280F2 | SH280FG-2 | SH280FG | |

| SH300 | SH340 | SH340EJ | SH340F1 | SH340F2 | SH350 | |

| SH160 | SH160-2 | SH430 | SH430FJ | LS280 | SH915 | |

| HYUNDAI | R55 | R60 | R80-8 | R130 | R170 | R180 |

| R200 | R200-5 | R210 | R210-3 | R210-5 | ||

| R220 | R220-5 | R300 | R250 | R250-5 | ||

| R305-7 | R310 | R320-7 | R335-7 | |||

| DAEWOO | DH55 | DH60 | DH60-5 | DH200-5 | ||

| DH220-2 | DH220-3 | DH220-5 | DH225-7 | DH250-7 | DH220-7 | |

| DH258-7 | DH280 | DH300 | ||||

More Excavator Spare Parts

| Engine Assembly | Final Drive Assy | Hydraulic Pump | Gear Pump |

| Swing Motor | Travel Motor | Fan Motor | Electrical Parts |

| Swing Gearbox | Travel Gearbox | Relief Valve | Distribution Valve |

| Available Engine Parts | Radiator | Main Valve | Belt |

| Liner Kit | Piston | Piston Ring | Engine Bearing |

| Cylinder Block | Gasket Kit | Gasket Head | Crankshaft |

| Valve | Valve Seat | Valve Xihu (West Lake) Dis. | Nozzle |

| Bearing | Accelerator Motor | Transmitter | Pressure Switch |

| Flameout Solenoid | Monitor | Fan Cooling | Oil Filter |

Company Profile

Xihu (West Lake) Dis.an Machiney Equipment Co., Ltd.

HangZhou Xihu (West Lake) Dis.an Machinery Co., Ltd (EB Seals) is a professional supplier for hydraulic breaker parts and excavator parts and OEM hydraulic seals manufacturer. We specialize in completed seal kits and separate seals for hydraulic breaker and excavator more than Ten years in HangZhou, China.

HangZhou Xihu (West Lake) Dis.an supply almost all brands breakers’ parts like Seal kits, Diaphragm, Piston, Chisel, Wear Bush upper and lower, Rod Pin, Through Bolts, Side Bolts, Control Valve,Front Head, Cylinder, Accumulator, N2 Gas Charging Kit, etc. We insist on high quality parts with genuine and OEM after market replacement parts.

Specializes in:

–Hydraulic hammer breaker

–Hydraulic breaker parts

Our Service

1. We have advanced technology, professional team and 100% testing by comprehensive power hydraulic pump testing facilities originally or China made.

2. Competitive price to support the qualified hydraulic pumps to you.

3. The larger quantity you order, the better price and faster delivery we can supply

Certifications

Our product have been supplied to over 70 companies of more than 30 countries

Certificate such as CE, ISO, can also be a proof of our quality.

After Sales Service

After sending, we will track the products for you once every 2 days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

FAQ

Q1. How many days for the delivery time ?

It is about 3-7 working days after the order confirmation.

Q2. What kind of payments you accept?

Now we accept T/T, L/C or Western Union, other terms also could be negotiated, Recommended Trade Assurance to guarantee buyer’s property.

Q3. Are you CZPT to manufacturing products according to customer’s design?

Sure, we have made many special orders from oversea for 15 years. So we have enough ability to deal with any cases. OEM certificate is available to provided.

Q4. What’s your advantages in the machinery manufacturing industry?

Fast delivery time, High quality products, Best customer service, Adopting the latest production technology.

Q5. Which countries have you been exported recently?

Canada, Australia, Peru, Egypt, Brazil, Mexico, South Africa, etc.

Q6. Are you sure that your product will fit my excavator?

We have different brand hydraulic breaker. Show me your model number or how many tons excavator, and we can give you best match products.

Q7. How about the packing of the goods?

Standard export package, wood cases, or as customers’ demands.

| Application: | Excavator |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Type: | Planetary Gear Box |

| Machine: | Excavator |

| Model Number: | E305.5 E304 E305cr E306 |

| Modification: | with Motor |

| Customization: |

Available

| Customized Request |

|---|

How to Maximize Gear Motor Reliability

A gearmotor is a mechanical device used to transmit torque from one location to another. As its name implies, it is designed to rotate one object relative to another. Its main use is to transmit torque from one point to another. The most common types of gear motors are: worm, spur, and helical. Each of these has specific functions and can be used for a variety of applications. Reliability is also an important factor to consider when choosing a gearmotor.

Applications of a gear motor

Despite its small size, a gear motor has many applications. These include heavy machinery lifts, hospital beds, and power recliners. It is also found in many everyday products, such as electromechanical clocks and cake mixers. Its versatility allows it to produce a high force from a small electric motor. Here are some of its most common uses. You can also find a gear motor in many household appliances and vehicles.

Before selecting a gearmotor, consider the specifications of the machine you need to power. You should consider its size, weight, and ambient conditions, which include temperature regimes, noise levels, and contaminating sources. You should also take into account the envelope size, mounting method, and orientation. Other considerations include the expected service life, maintenance scope, and control type. The most suitable gearmotor for your specific application will be one that can handle the load.