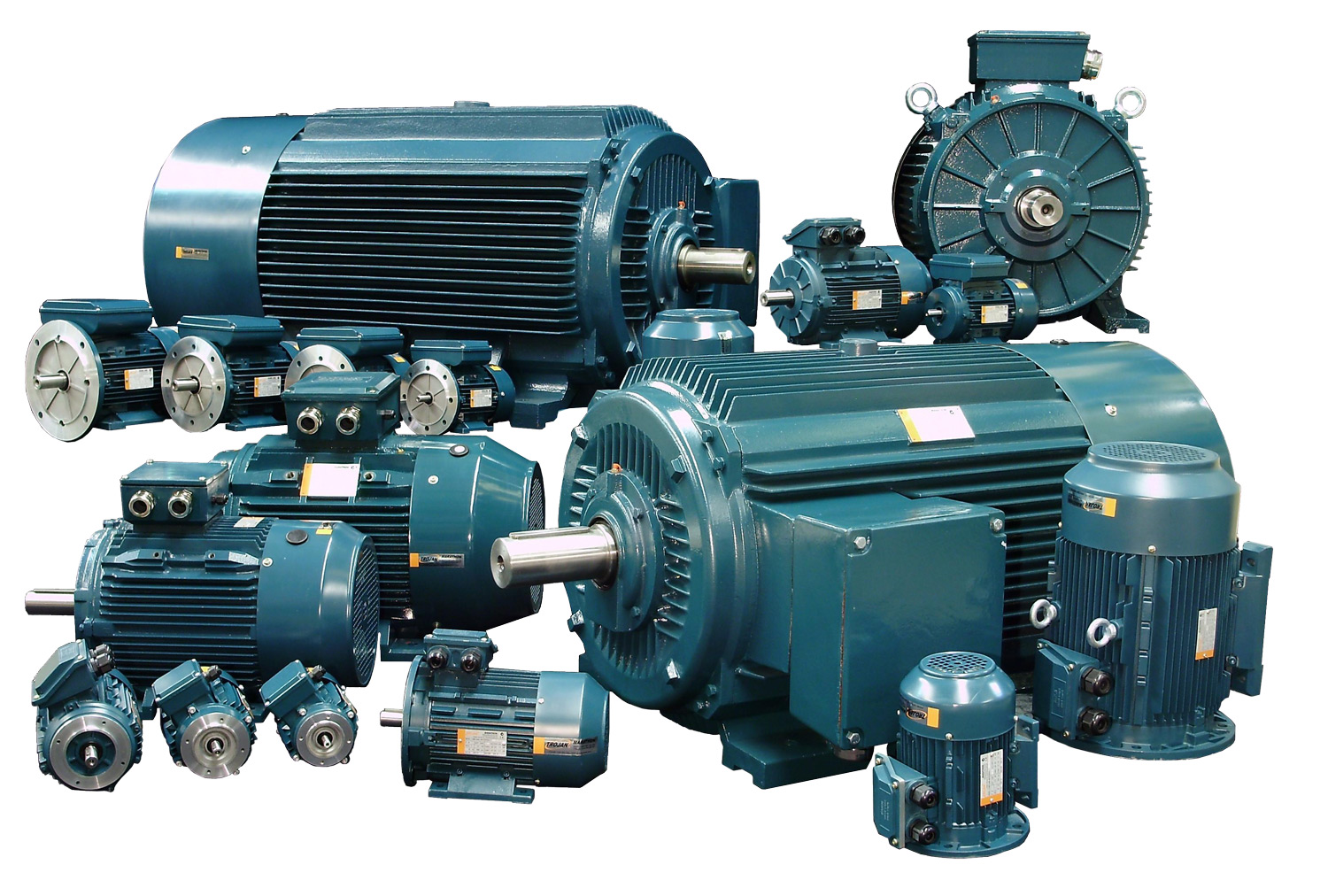

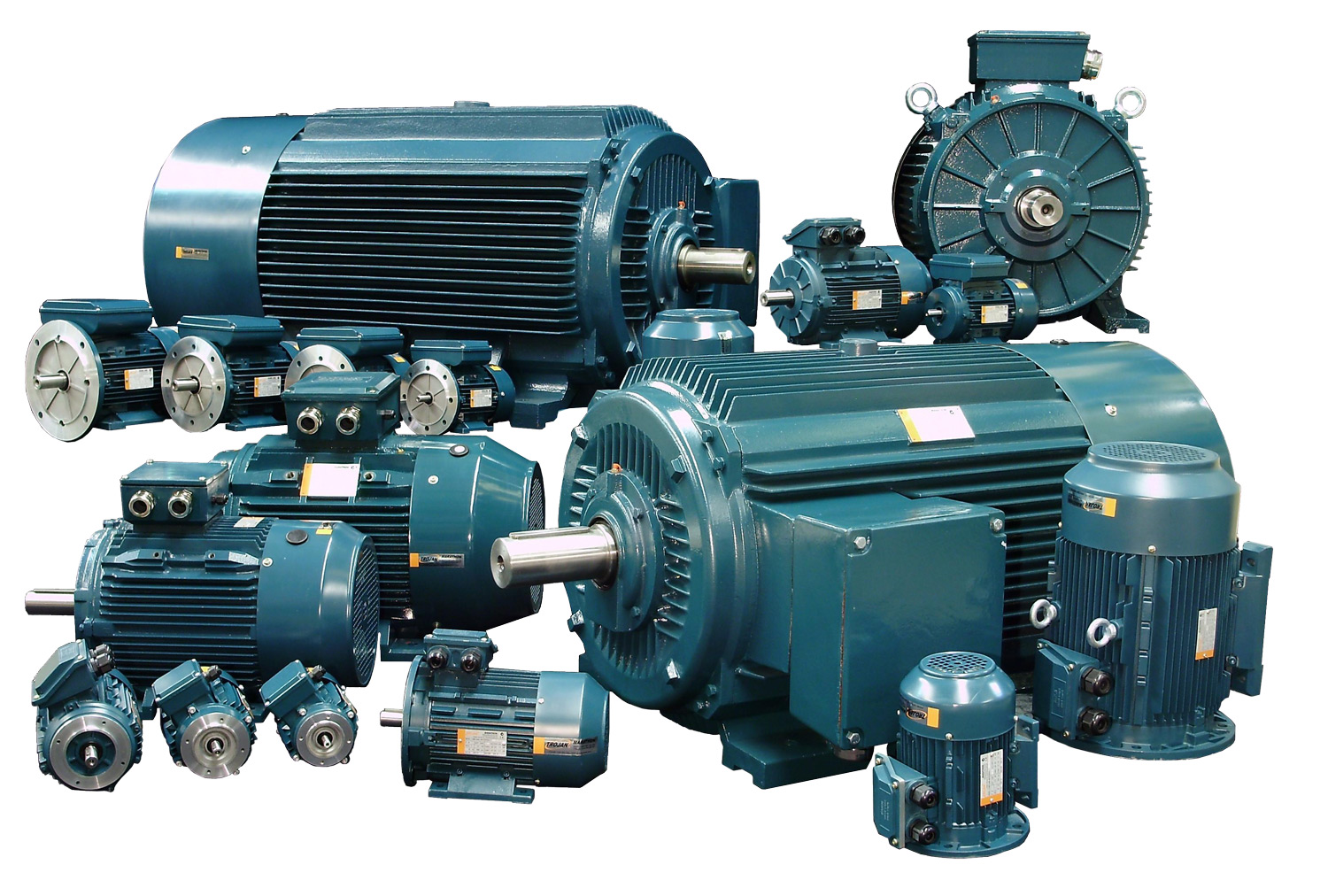

Product Description

| Frequency | 50Hz/60Hz |

| Motor Type | AC Motor |

| Rotation | CW/CCW |

| Inspection | Full Inspection |

Please click this text for more product information. Thank you!

1.

Location

Kexionda Electric Machinery Manufacturing Co., Ltd. (KXD) was established in 1998 and is located in the hinterland of the Pearl River CHINAMFG in South China. It is a professional enterprise that develops and produces micromotors. It now has a factory area of more than 10,000 square meters, more than 200 employees, and an annual output of 5 million motors. It mainly produces single-phase series motors (universal motors) and permanent magnet-brushed DC motors. The products are suitable for household appliances, commercial appliances, and electric equipment, such as mixers, egg beaters, meat grinders, meat mincers, ice crushers, paper shredders, bean grinders, soy milk machines, cooking machines, cloth machines, laboratory homogenizer and a series of electric products.

2.

“integrity and pragmatism”

Since its establishment, KXD has continued to innovate and win the market with integrity. The company comprehensively implements modern management, conducts production and sales based on the principle of benefiting customers, produces key parts of products by itself, continuously introduces automated production equipment, takes “quality and service” as its life, “integrity and pragmatism” as its foundation, and through its own Design, production, and management are integrated to meet customer delivery deadlines to the greatest extent, effectively control product quality and reduce costs.

3.

Production standards

KXD strictly implements national standards during the production process, establishes and maintains the effective operation of the quality management system, and all products have 100% passed domestic CCC certification. All export products comply with Rohs and can pass EMC, UL, CE, VDE, and other certification requirements.

4.

Customer – first

At present, our company has dedicated project personnel to track product development, production, and after-sales service throughout the entire process, and is committed to providing customers with high-quality product solutions.

Q1: Are you a trading company or manufacturer?

A1: We are a manufacturer located in HangZhou, GUANXIHU (WEST LAKE) DIS., CHINA.

Q2: Do you provide a sample? Is it free or extra?

A2: Sample can be on request and not for free

Q3: Do you provide OEM design?

A3: OEM motor/cartons/gift box/label are available

please feel free to send us your motor drawing and other information we could supply

some designed drawings for optional.

Q4: What is your lead time?

A4: “-It depends on the order quantity and the season you place the order. -Usually, we can ship within 15-20 days for regular orders and about 30 days for customized orders”

Q5: What is your payment term?

A5: Payment Term: T/T(30% deposit 70% balance payment against B/L copy) or L/C at sight. This is negotiable.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Household Appliances, Power Tools |

|---|---|

| Operating Speed: | Adjust Speed |

| Number of Stator: | Single-Phase |

| Species: | YVP Series Frequency Control |

| Rotor Structure: | Winding Type |

| Casing Protection: | Protection Type |

| Samples: |

US$ 12/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does an electric motor ensure efficient energy conversion?

An electric motor ensures efficient energy conversion by employing various design features and principles that minimize energy losses and maximize the conversion of electrical energy into mechanical energy. Here’s a detailed explanation of how electric motors achieve efficient energy conversion:

- Efficient Motor Design: Electric motors are designed with careful consideration given to their construction and materials. High-quality magnetic materials, such as laminated iron cores and permanent magnets, are used to reduce magnetic losses and maximize magnetic field strength. Additionally, the motor’s windings are designed with low-resistance conductors to minimize electrical losses. By optimizing the motor’s design, manufacturers can improve its overall efficiency.

- Reducing Friction and Mechanical Losses: Electric motors are designed to minimize friction and mechanical losses. This is achieved through the use of high-quality bearings and lubrication systems that reduce friction between moving parts. By reducing friction, the motor can operate more efficiently, translating more of the input energy into useful mechanical work rather than dissipating it as heat.

- Efficient Control and Power Electronics: Electric motors employ advanced control techniques and power electronics to enhance energy conversion efficiency. Variable frequency drives (VFDs) are commonly used to control motor speed and torque, allowing the motor to operate at optimal efficiency levels under varying load conditions. Power electronics devices, such as insulated gate bipolar transistors (IGBTs) and MOSFETs, minimize switching losses and optimize power flow within the motor.

- Regenerative Braking and Energy Recovery: Some electric motors, particularly those used in hybrid electric vehicles (HEVs) and electric trains, incorporate regenerative braking systems. These systems convert the kinetic energy of the moving vehicle back into electrical energy, which can be stored and reused. By capturing and reusing energy that would otherwise be wasted as heat during braking, regenerative braking significantly improves overall energy efficiency.

- Efficient Cooling and Thermal Management: Electric motors generate heat during operation, and excessive heat can lead to energy losses and reduced efficiency. To mitigate this, motors are designed with efficient cooling systems such as fans, heat sinks, or liquid cooling methods. Proper thermal management ensures that the motor operates within the optimal temperature range, reducing losses and improving overall efficiency.

- High-Efficiency Standards and Regulations: Governments and organizations have established energy efficiency standards and regulations for electric motors. These standards encourage manufacturers to produce motors with higher efficiency ratings. Compliance with these standards ensures that motors meet certain efficiency criteria, resulting in improved energy conversion and reduced energy consumption.

By incorporating these design features, control techniques, and efficiency measures, electric motors achieve efficient energy conversion. They minimize energy losses due to factors such as resistance, friction, and heat dissipation, ensuring that a significant portion of the input electrical energy is converted into useful mechanical work. The continuous advancements in motor design, materials, and control technologies further contribute to improving the overall energy efficiency of electric motors.

What advancements in electric motor technology have improved energy efficiency?

Advancements in electric motor technology have played a crucial role in improving energy efficiency, leading to more sustainable and environmentally friendly applications. Here’s a detailed explanation of some key advancements in electric motor technology that have contributed to enhanced energy efficiency:

- High-Efficiency Motor Designs: One significant advancement in electric motor technology is the development of high-efficiency motor designs. These designs focus on reducing energy losses during motor operation, resulting in improved overall efficiency. High-efficiency motors are engineered with optimized stator and rotor geometries, reduced core losses, and improved magnetic materials. These design enhancements minimize energy wastage and increase the motor’s efficiency, allowing it to convert a higher percentage of electrical input power into useful mechanical output power.

- Premium Efficiency Standards: Another notable advancement is the establishment and adoption of premium efficiency standards for electric motors. These standards, such as the International Electrotechnical Commission (IEC) IE3 and NEMA Premium efficiency standards, set minimum efficiency requirements for motors. Manufacturers strive to meet or exceed these standards by incorporating innovative technologies and design features that enhance energy efficiency. The implementation of premium efficiency standards has led to the widespread availability of more efficient motors in the market, encouraging energy-conscious choices and reducing energy consumption in various applications.

- Variable Speed Drives: Electric motor systems often operate under varying load conditions, and traditional motor designs operate at a fixed speed. However, the development and adoption of variable speed drives (VSDs) have revolutionized motor efficiency. VSDs, such as frequency converters or inverters, allow the motor’s speed to be adjusted according to the load requirements. By operating motors at the optimal speed for each task, VSDs minimize energy losses and significantly improve energy efficiency. This technology is particularly beneficial in applications with variable loads, such as HVAC systems, pumps, and conveyors.

- Improved Motor Control and Control Algorithms: Advanced motor control techniques and algorithms have contributed to improved energy efficiency. These control systems employ sophisticated algorithms to optimize motor performance, including speed control, torque control, and power factor correction. By precisely adjusting motor parameters based on real-time operating conditions, these control systems minimize energy losses and maximize motor efficiency. Additionally, the integration of sensor technology and feedback loops enables closed-loop control, allowing motors to respond dynamically and adaptively to changes in load demand, further enhancing energy efficiency.

- Use of Permanent Magnet Motors: Permanent magnet (PM) motors have gained popularity due to their inherent high energy efficiency. PM motors utilize permanent magnets in the rotor, eliminating the need for rotor windings and reducing rotor losses. This design enables PM motors to achieve higher power densities, improved efficiency, and enhanced performance compared to traditional induction motors. The use of PM motors is particularly prevalent in applications where high efficiency and compact size are critical, such as electric vehicles, appliances, and industrial machinery.

- Integration of Advanced Materials: Advances in materials science have contributed to improved motor efficiency. The utilization of advanced magnetic materials, such as rare-earth magnets, allows for stronger and more efficient magnetic fields, resulting in higher motor efficiency. Additionally, the development of low-loss electrical steel laminations and improved insulation materials reduces core losses and minimizes energy wastage. These advanced materials enhance the overall efficiency of electric motors, making them more energy-efficient and environmentally friendly.

The advancements in electric motor technology, including high-efficiency motor designs, premium efficiency standards, variable speed drives, improved motor control, permanent magnet motors, and advanced materials, have collectively driven significant improvements in energy efficiency. These advancements have led to more efficient motor systems, reduced energy consumption, and increased sustainability across a wide range of applications, including industrial machinery, transportation, HVAC systems, appliances, and renewable energy systems.

What are the different types of electric motors available?

There are various types of electric motors available, each designed for specific applications and operating principles. These motors differ in their construction, power sources, and performance characteristics. Here is an overview of some common types of electric motors:

- DC Motors: DC (Direct Current) motors are widely used and come in different configurations. The most common types include brushed DC motors and brushless DC motors. Brushed DC motors use brushes and a commutator to switch the direction of current in the rotor, while brushless DC motors use electronic commutation. DC motors offer good speed control and torque characteristics, making them suitable for applications like robotics, electric vehicles, and small appliances.

- AC Motors: AC (Alternating Current) motors are classified into several types, including induction motors, synchronous motors, and universal motors. Induction motors are popular for their simplicity and reliability. They operate based on electromagnetic induction and are commonly used in industrial and residential applications. Synchronous motors operate at a constant speed and are often used in applications that require precise control, such as industrial machinery and synchronous clocks. Universal motors are designed to operate on both AC and DC power sources and are commonly found in household appliances like vacuum cleaners and power tools.

- Stepper Motors: Stepper motors are designed to move in discrete steps or increments, making them suitable for applications that require precise positioning. They are often used in robotics, 3D printers, CNC machines, and other automated systems. Stepper motors are available in various configurations, including permanent magnet stepper motors, variable reluctance stepper motors, and hybrid stepper motors.

- Servo Motors: Servo motors are a type of motor that combines a DC motor with a feedback control mechanism. They are known for their precise control over position, velocity, and acceleration. Servo motors are commonly used in robotics, industrial automation, and applications that require accurate motion control, such as robotic arms, RC vehicles, and camera gimbals.

- Linear Motors: Linear motors are designed to produce linear motion instead of rotational motion. They operate on similar principles as rotary motors but with a different mechanical arrangement. Linear motors find applications in high-speed transportation systems, cutting machines, and other systems that require linear motion without the need for mechanical conversion from rotary to linear motion.

- Haptic Motors: Haptic motors, also known as vibration motors, are small motors used to create tactile feedback or vibrations in electronic devices. They are commonly found in smartphones, game controllers, wearable devices, and other gadgets that require haptic feedback to enhance the user experience.

These are just a few examples of the different types of electric motors available. Each type has its own advantages, limitations, and specific applications. The selection of an electric motor depends on factors such as the required torque, speed, control, efficiency, and the specific needs of the application at hand.

editor by CX 2024-05-15

China best Manufacture Motor 5425 Universal Household Appliances Meat Grinder Electric Motor vacuum pump connector

Product Description

Product Description

| Operating Voltage | 1)100~120V/50/60Hz 2)220~240V/50/60Hz |

| Motor speed | No load: 18000~30000RPM Load: 8000~20000RPM |

| Nominal power | 150-250W |

| Shaft diameter | Ø6.35 &Ø7.14 |

| Stator winding type | Ordinary inner winding & automatic wire frame structure |

| enameled wire | 1) Stator: copper wire & copper clad aluminum & aluminum wire; 2) Rotor: copper wire |

| protector | Fuses & Thermal Protectors |

| Main application | Bean Grinders & Meat Grinders & Food Processors & Paper Shredders & Hair Dryers & Soy Milk Makers & Hand Blenders & Personal Blenders |

Recommend Products

Company Profile

Packaging & Shipping

FAQ

Q1: What kind motors you can provide?

A1: For now, we mainly provide permanent magnet brush dc motors, brushless dc motor, dc gear motor, micro dc motor, ac gear motor, planetary gear motor, with diameter range in 42~110mm.

Q2: Is there a MOQ for your motors?

A2: No. we can accept 1 pcs for sample making for your testing,and the price for sample making will have 30% to 50% difference based on different style.

Q3: Could you send me a price list?

A3: For all of our motors, they are customized based on different requirements like power, voltage, gear ratio, rated torque and shaft diameter etc. The price also varies according to different order qty. So it’s really difficult for us to provide a price list. If you can share your detailed specification and order qty, we’ll see what offer we can provide.

Q4: Are you motors reversible?

A4: Yes, nearly all dc and ac motor are reversible. We have technical people who can teach how to get the function by different wire connection.

Q5:How about your delivery time?

A5: For micro brush dc gear motor, the sample delivery time is 2-5 days, bulk delivery time is about 15-20 days, depends on the order qty. For brushless dc motor, the sample deliver time is about 10-15 days; bulk time is 15-20 days.Please take the sales confirmation for final reference.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal |

|---|---|

| Speed: | High Speed |

| Function: | Control |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

Can electric motors be used in renewable energy systems like wind turbines?

Yes, electric motors can be used in renewable energy systems like wind turbines. In fact, electric motors play a crucial role in converting the kinetic energy of the wind into electrical energy in wind turbines. Here’s a detailed explanation of how electric motors are utilized in wind turbines and their role in renewable energy systems:

Wind turbines are designed to capture the energy from the wind and convert it into electrical power. Electric motors are used in wind turbines to drive the rotation of the turbine blades and generate electricity through the following process:

- Wind Capture: The wind turbine blades are designed to efficiently capture the kinetic energy of the wind. As the wind blows, it causes the blades to rotate.

- Blade Rotation: The rotational motion of the turbine blades is achieved through electric motors known as pitch motors. Pitch motors adjust the angle or pitch of the blades to optimize their orientation relative to the wind direction. The electric motors drive the mechanical mechanism that rotates the blades, allowing them to capture the maximum energy from the wind.

- Power Generation: The rotation of the wind turbine blades drives the main shaft of the turbine, which is connected to an electric generator. The generator consists of another electric motor known as the generator motor or generator rotor. The rotational motion of the generator rotor within a magnetic field induces an electrical current in the generator’s stator windings, producing electricity.

- Power Conversion and Distribution: The electricity generated by the wind turbine’s generator motor is typically in the form of alternating current (AC). To make it compatible with the electrical grid or local power system, the AC power is converted to the appropriate voltage and frequency using power electronics such as inverters. These power electronics may also incorporate electric motors for various conversion and control functions.

- Integration with Renewable Energy Systems: Wind turbines, equipped with electric motors, are integrated into renewable energy systems to contribute to the generation of clean and sustainable power. Multiple wind turbines can be connected together to form wind farms, which collectively generate significant amounts of electricity. The electricity produced by wind turbines can be fed into the electrical grid, used to power local communities, or stored in energy storage systems for later use.

Electric motors in wind turbines enable the efficient conversion of wind energy into electrical energy, making wind power a viable and renewable energy source. The advancements in motor and generator technologies, along with control systems and power electronics, have enhanced the performance, reliability, and overall efficiency of wind turbines. Additionally, electric motors allow for precise control and adjustment of the turbine blades, optimizing the energy capture and minimizing the impact of varying wind conditions.

Overall, the use of electric motors in wind turbines is instrumental in harnessing the power of wind and contributing to the generation of clean and sustainable energy in renewable energy systems.

Can you explain the basic principles of electric motor operation?

An electric motor operates based on several fundamental principles of electromagnetism and electromagnetic induction. These principles govern the conversion of electrical energy into mechanical energy, enabling the motor to generate rotational motion. Here’s a detailed explanation of the basic principles of electric motor operation:

- Magnetic Fields: Electric motors utilize magnetic fields to create the forces necessary for rotation. The motor consists of two main components: the stator and the rotor. The stator contains coils of wire wound around a core and is responsible for generating a magnetic field. The rotor, which is connected to the motor’s output shaft, has magnets or electromagnets that produce their own magnetic fields.

- Magnetic Field Interaction: When an electric current flows through the coils in the stator, it generates a magnetic field. This magnetic field interacts with the magnetic field produced by the rotor. The interaction between these two magnetic fields results in a rotational force, known as torque, that causes the rotor to rotate.

- Electromagnetic Induction: Electric motors can also operate on the principle of electromagnetic induction. In these motors, alternating current (AC) is supplied to the stator coils. The alternating current produces a changing magnetic field that induces a voltage in the rotor. This induced voltage then generates a current in the rotor, which creates its own magnetic field. The interaction between the stator’s magnetic field and the rotor’s magnetic field leads to rotation.

- Commutation: In certain types of electric motors, such as brushed DC motors, commutation is employed. Commutation refers to the process of reversing the direction of the current in the rotor’s electromagnets to maintain continuous rotation. This is achieved using a component called a commutator, which periodically switches the direction of the current as the rotor rotates. By reversing the current at the right time, the commutator ensures that the magnetic fields of the stator and the rotor remain properly aligned, resulting in continuous rotation.

- Output Shaft: The rotational motion generated by the interaction of magnetic fields is transferred to the motor’s output shaft. The output shaft is connected to the load or the device that needs to be driven, such as a fan, a pump, or a conveyor belt. As the motor rotates, the mechanical energy produced is transmitted through the output shaft, enabling the motor to perform useful work.

In summary, the basic principles of electric motor operation involve the generation and interaction of magnetic fields. By supplying an electric current to the stator and utilizing magnets or electromagnets in the rotor, electric motors create magnetic fields that interact to produce rotational motion. Additionally, the principle of electromagnetic induction allows for the conversion of alternating current into mechanical motion. Commutation, in certain motor types, ensures continuous rotation by reversing the current in the rotor’s electromagnets. The resulting rotational motion is then transferred to the motor’s output shaft to perform mechanical work.

editor by CX 2024-04-16

China wholesaler Electric 54mm 350W Universal AC Motor for Grass Trimmer brushless motor

Product Description

Product Description

Detailed Photos

|

Product Name: |

Universal Motor |

|

Model No. |

54 |

|

Brand: |

LHangZhou |

|

Application: |

String Timmers |

|

Rated Voltage: |

230V |

|

Rated Power: |

350W |

|

Rated Torque: |

0.15N.m |

|

Rated Speed: |

11000rpm |

|

Customized: |

yes |

|

Positive Inversion: |

yes |

|

Packing: |

foam&carton,or accroding to customers’ specific requirements |

|

MOQ: |

3000 pcs |

|

Delivery Time: |

Depends on quantity from 2 weeks to 4 weeks. |

|

Payment Term: |

T/T, L/C, D/P |

Application

Company Profile

FAQ

1.What’re your main products ?

We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

2. How to select a suitable motor?

If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

3.Do you have a customized service for your standard motors?

Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

4. Do you have an individual design service for motors?

Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

5. Can I have samples for testing first?

Yes, definitely you can. After confirmed the needed motor specs, we will quote and provide a proforma invoice for samples, once we get the payment, we will get a PASS from our account department to proceed samples accordingly.

6.How do you make sure motor quality?

We have our own inspection procedures: for incoming materials, we have signed sample and drawing to make sure qualified incoming materials; for production process, we have tour inspection in the process and final inspection to make sure qualified products before shipping.

7.What’s your lead time?

Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Weclome contact with us if have any questions about this motor or other products!

| Application: | Four Wheel Mower |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Single-Phase |

| Function: | Driving |

| Casing Protection: | Protection Type |

| Number of Poles: | 2 |

| Samples: |

US$ 7/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Benefits of a Planetary Motor

A planetary motor has many benefits. Its compact design and low noise makes it a good choice for any application. Among its many uses, planetary gear motors are found in smart cars, consumer electronics, intelligent robots, communication equipment, and medical technology. They can even be found in smart homes! Read on to discover the benefits of a planetary gear motor. You’ll be amazed at how versatile and useful it is!

Self-centering planet gears ensure a symmetrical force distribution

A planetary motor is a machine with multiple, interlocking planetary gears. The output torque is inversely proportional to the diameters of the planets, and the transmission size has no bearing on the output torque. A torsional stress analysis of the retaining structure for this type of motor found a maximum shear stress of 64 MPa, which is equivalent to a safety factor of 3.1 for 6061 aluminum. Self-centering planet gears are designed to ensure a symmetrical force distribution throughout the transmission system, with the weakest component being the pinions.

A planetary gearbox consists of ring and sun gears. The pitch diameters of ring and planet gears are nearly equal. The number of teeth on these gears determines the average gear-ratio per output revolution. This error is related to the manufacturing precision of the gears. The effect of this error is a noise or vibration characteristic of the planetary gearbox.

Another design for a planetary gearbox is a traction-based variant. This design eliminates the need for timing marks and other restrictive assembly conditions. The design of the ring gear is similar to that of a pencil sharpener mechanism. The ring gear is stationary while planet gears extend into cylindrical cutters. When placed on the sun’s axis, the pencil sharpening mechanism revolves around the ring gear to sharpen the pencil.

The JDS eliminates the need for conventional planetary carriers and is mated with the self-centering planet gears by dual-function components. The dual-function components synchronize the rolling motion and traction of the gears. They also eliminate the need for a carrier and reduce the force distribution between the rotor and stator.

Metal gears

A planetary motor is a type of electric drive that uses a series of metal gears. These gears share a load attached to the output shaft to generate torque. The planetary motor is often CNC controlled, with extra-long shafts, which allow it to fit into very compact designs. These gears are available in sizes from seven millimeters to 12 millimeters. They can also be fitted with encoders.

Planetary gearing is widely used in various industrial applications, including automobile transmissions, off-road transmissions, and wheel drive motors. They are also used in bicycles to power the shift mechanism. Another use for planetary gearing is as a powertrain between an internal combustion engine and an electric motor. They are also used in forestry applications, such as debarking equipment and sawing. They can be used in other industries as well, such as pulp washers and asphalt mixers.

Planetary gear sets are composed of three types of gears: a sun gear, planet gears, and an outer ring. The sun gear transfers torque to the planet gears, and the planet gears mesh with the outer ring gear. Planet carriers are designed to deliver high-torque output at low speeds. These gears are mounted on carriers that are moved around the ring gear. The planet gears mesh with the ring gears, and the sun gear is mounted on a moveable carrier.

Plastic planetary gear motors are less expensive to produce than their metal counterparts. However, plastic gears suffer from reduced strength, rigidity, and load capacity. Metal gears are generally easier to manufacture and have less backlash. Plastic planetary gear motor bodies are also lighter and less noisy. Some of the largest plastic planetary gear motors are made in collaboration with leading suppliers. When buying a plastic planetary gear motor, be sure to consider what materials it is made of.

Encoder

The Mega Torque Planetary Encoder DC Geared Motor is designed with a Japanese Mabuchi motor RS-775WC, a 200 RPM base motor. It is capable of achieving stall torque at low speeds, which is impossible to achieve with a simple DC motor. The planetary encoder provides five pulses per revolution, making it perfect for applications requiring precise torque or position. This motor requires an 8mm hex coupling for proper use.

This encoder has a high resolution and is suitable for ZGX38REE, ZGX45RGG and ZGX50RHH. It features a magnetic disc and poles and an optical disc to feed back signals. It can count paulses as the motor passes through a hall on the circuit board. Depending on the gearbox ratio, the encoder can provide up to two million transitions per rotation.

The planetary gear motor uses a planetary gear system to distribute torque in synchrony. This minimizes the risk of gear failure and increases the overall output capacity of the device. On the other hand, a spur gear motor is a simpler design and cheaper to produce. The spur gear motor works better for lower torque applications as each gear bears all the load. As such, the torque capacity of the spur gear motor is lower than that of a planetary gear motor.

The REV UltraPlanetary gearbox is designed for FTC and has three different output shaft options. The output shaft is made of 3/8-inch hex, allowing for flexible shaft replacement. These motors are a great value as they can be used to meet a wide range of power requirements. The REV UltraPlanetary gearbox and motor are available for very reasonable prices and a female 5mm hex output shaft can be used.

Durability

One of the most common questions when selecting a planetary motor is “How durable is it?” This is a question that’s often asked by people. The good news is that planetary motors are extremely durable and can last for a long time if properly maintained. For more information, read on! This article will cover the durability and efficiency of planetary gearmotors and how you can choose the best one for your needs.

First and foremost, planetary gear sets are made from metal materials. This increases their lifespan. The planetary gear set is typically made of metals such as nickel-steel and steel. Some planetary gear motors use plastic. Steel-cut gears are the most durable and suitable for applications that require more torque. Nickel-steel gears are less durable, but are better able to hold lubricant.

Durability of planetary motor gearbox is important for applications requiring high torque versus speed. VEX VersaPlanetary gearboxes are designed for FRC(r) use and are incredibly durable. They are expensive, but they are highly customizable. The planetary gearbox can be removed for maintenance and replacement if necessary. Parts for the gearbox can be purchased separately. VEX VersaPlanetary gearboxes also feature a pinion clamped onto the motor shaft.

Dynamic modeling of the planetary gear transmission system is important for understanding its durability. In previous studies, uncoupled and coupled meshing models were used to investigate the effect of various design parameters on the vibration characteristics of the planetary gear system. This analysis requires considering the role of the mesh stiffness, structure stiffness, and moment of inertia. Moreover, dynamic models for planetary gear transmission require modeling the influence of multiple parameters, such as mesh stiffness and shaft location.

Cost

The planetary gear motor has multiple contact points that help the rotor rotate at different speeds and torques. This design is often used in stirrers and large vats of liquid. This type of motor has a low initial cost and is more commonly found in low-torque applications. A planetary gear motor has multiple contact points and is more effective for applications requiring high torque. Gear motors are often found in stirring mechanisms and conveyor belts.

A planetary gearmotor is typically made from four mechanically linked rotors. They can be used for various applications, including automotive and laboratory automation. The plastic input stage gears reduce noise at higher speeds. Steel gears can be used for high torques and a modified lubricant is often added to reduce weight and mass moment of inertia. Its low-cost design makes it an excellent choice for robots and other applications.

There are many different types of planetary gear motors available. A planetary gear motor has three gears, the sun gear and planet gears, with each sharing equal amounts of work. They are ideal for applications requiring high torque and low-resistance operation, but they require more parts than their single-stage counterparts. The steel cut gears are the most durable, and are often used in applications that require high speeds. The nickel-steel gears are more absorptive, which makes them better for holding lubricant.

A planetary gear motor is a high-performance electrical vehicle motor. A typical planetary gear motor has a 3000 rpm speed, a peak torque of 0.32 Nm, and is available in 24V, 36V, and 48V power supply. It is also quiet and efficient, requiring little maintenance and offering greater torque to a modern electric car. If you are thinking of buying a planetary gear motor, be sure to do a bit of research before purchasing one.

editor by CX 2023-11-23

China high quality (IE3/IE2) Ye3-100L-2 (3kW/4HP) Three Phase AC Electric Motor CCC CE for Pump Fans Universal Machines OEM ODM Obm High Efficiency Motor IEC Standard vacuum pump for ac

Product Description

(IE3/IE2) Ye3-100L-2 (3kW/4HP) Three phase AC Electric Motor CCC CE for Pump Fans Universal Machines OEM ODM OBM High Efficiency Motor IEC Standard

The YE3 Three-phase Electric Motor, with the latest design in its entirety, is made of selected quality materials and conforms to the IEC standard.

1. Product Introduction

(IE3/IE2) Ye3-100L-2 (3kW/4HP) Three phase AC Electric Motor CCC CE for Pump Fans Universal Machines OEM ODM OBM High Efficiency Motor IEC Standard have good performance, safety and reliable operation, nice appearance, and can be maintained very conveniently, while with low noise. little vibration,at the same time, lightweight and simple construction. These motors can be used for general drives.

| Type: | Asynchronous motor |

| Efficiency: | IE 3 |

| Rated frequency: | 50Hz |

| Rated voltage: | 220V, 380V, 660V, 220/380V, 380/660V |

| Output power: | 0.75~450KW |

| Duty: | Continuous (S1) |

| Altitude: | not exceeding 1000m |

| Ambient temperature: | varies with seasons, but no more than 40 °C |

| Place of origin: | ZHangZhoug, China(mainland) |

2. Products Parameter

| Type | Amps | Watts(HP) | Speed(R/Min) | Eff.% | Cos.fi | Tsn/In | Isn/In | Tmax/Tn |

| YE3-80M1-2 | 1.7 | 1.1 | 2880 | 80.7 | 0.82 | 2.3 | 7 | 2.3 |

| YE3-80M2-2 | 2.4 | 1.5 | 2880 | 82.7 | 0.83 | 2.2 | 7.3 | 2.3 |

| YE3-90S-2 | 3.2 | 2 | 2895 | 84.2 | 0.84 | 2.2 | 7.6 | 2.3 |

| YE3-90L-2 | 4.6 | 3 | 2895 | 85.9 | 0.85 | 2.2 | 7.6 | 2.3 |

| YE3-100L-2 | 6 | 4 | 2995 | 87.1 | 0.87 | 2.2 | 7.8 | 2.3 |

| YE3-112M-2 | 7.8 | 5.5 | 2905 | 88.1 | 0.88 | 2.2 | 8.3 | 2.3 |

| YE3-132S1-2 | 10.6 | 7.5 | 2930 | 89.2 | 0.88 | 2 | 8.3 | 2.3 |

| YE3-132S2-2 | 14.4 | 10 | 2930 | 90.1 | 0.88 | 2 | 7.9 | 2.3 |

| YE3-160M1-2 | 20.6 | 15 | 2945 | 91.2 | 0.89 | 2 | 8.1 | 2.3 |

| YE3-160M2-2 | 27.9 | 20 | 2945 | 91.9 | 0.89 | 2 | 8.1 | 2.3 |

| YE3-160L-2 | 34.2 | 25 | 2945 | 92.4 | 0.89 | 2 | 8.2 | 2.3 |

| YE3-180M-2 | 40.5 | 30 | 2960 | 92.7 | 0.89 | 2 | 8.2 | 2.3 |

| YE3-200L1-2 | 54.9 | 40 | 2955 | 93.3 | 0.89 | 2 | 7.6 | 2.3 |

| YE3-200L2-2 | 67.4 | 50 | 2955 | 93.7 | 0.89 | 2 | 7.6 | 2.3 |

| YE3-225M-2 | 80.8 | 60 | 2965 | 94 | 0.9 | 2 | 7.7 | 2.3 |

| YE3-250M-2 | 98.5 | 75 | 2970 | 94.3 | 0.9 | 2 | 7.7 | 2.3 |

| YE3-280S-2 | 133.7 | 100 | 2975 | 94.7 | 0.8 | 1.8 | 7.1 | 2.3 |

| YE3-280M-2 | 159.9 | 120 | 2975 | 95 | 0.9 | 1.8 | 7.1 | 2.3 |

3. Product Application

(IE3/IE2) Ye3-100L-2 (3kW/4HP) Three phase AC Electric Motor CCC CE for Pump Fans Universal Machines OEM ODM OBM High Efficiency Motor IEC Standard are a fully closed, self-fan cold mouse cage three-phase asynchronous motor manufactured with new materials, new techniques and optimized design,have high efficiency, high starting torque, low noise, more reasonable structure and cooling conditions mature. This series of motors for general purpose three-phase asynchronous motors. It can be used to drive a variety of general mechanical equipment, such as compressors, fans, pumps and other mechanical equipment, but also in petroleum, chemical, pharmaceutical, mining and other fields.

4. Related Products

5. CHINAMFG Factory &Workshop

6.Certificate

| Application: | Industrial |

|---|---|

| Speed: | High Speed |

| Number of Stator: | Three-Phase |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | 2 |

| Samples: |

US$ 130.00/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide examples of machinery or equipment that rely on electric motors?

Electric motors are extensively used in various machinery and equipment across different industries. They play a crucial role in converting electrical energy into mechanical energy to power a wide range of applications. Here are some examples of machinery and equipment that heavily rely on electric motors:

- Industrial Machinery: Electric motors are found in numerous industrial machinery and equipment, such as pumps, compressors, fans, conveyors, agitators, mixers, and machine tools. These motors provide the necessary power for moving fluids, gases, and materials, as well as driving mechanical processes in manufacturing, mining, construction, and other industrial applications.

- Electric Vehicles: Electric motors are the primary propulsion system in electric vehicles (EVs) and hybrid electric vehicles (HEVs). They provide the power needed to drive the wheels and propel the vehicle. Electric motors in EVs and HEVs offer high efficiency, instant torque, and regenerative braking capabilities, contributing to the advancement of sustainable transportation.

- Household Appliances: Many household appliances rely on electric motors for their operation. Examples include refrigerators, air conditioners, washing machines, dishwashers, vacuum cleaners, blenders, and electric fans. Electric motors enable the movement, cooling, or mechanical functions in these appliances, enhancing convenience and efficiency in daily household tasks.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for various functions. Motors power the fans in air handling units, circulate air through ducts, and drive compressors in air conditioning and refrigeration systems. Electric motors in HVAC systems contribute to efficient temperature control and air circulation in residential, commercial, and industrial buildings.

- Medical Equipment: Electric motors are essential components in a wide array of medical equipment. Examples include MRI machines, X-ray machines, CT scanners, surgical robots, dental drills, infusion pumps, and patient lifts. These motors enable precise movements, imaging capabilities, and mechanical functions in medical devices, supporting diagnostics, treatment, and patient care.

- Power Tools: Electric motors are commonly used in power tools such as drills, saws, grinders, sanders, and routers. They provide the rotational force and power required for cutting, shaping, drilling, and other tasks. Electric motors in power tools offer portability, ease of use, and consistent performance for both professional and DIY applications.

- Aircraft Systems: Electric motors are increasingly utilized in aircraft systems. They power various components, including landing gear actuation systems, fuel pumps, hydraulic systems, and cabin air circulation systems. Electric motors in aircraft contribute to weight reduction, energy efficiency, and improved reliability compared to traditional hydraulic or pneumatic systems.

These examples represent just a fraction of the machinery and equipment that rely on electric motors. From industrial applications to household appliances and transportation systems, electric motors are integral to modern technology, providing efficient and reliable mechanical power for a wide range of purposes.

What safety precautions should be followed when working with electric motors?

Working with electric motors requires adherence to specific safety precautions to ensure the well-being of individuals and prevent accidents. Electric motors involve electrical hazards that can cause electric shock, burns, or other injuries if proper safety measures are not followed. Here’s a detailed explanation of the safety precautions that should be followed when working with electric motors:

- Qualified Personnel: It is important to assign work on electric motors to qualified personnel who have the necessary knowledge, training, and experience in electrical systems and motor operation. Qualified electricians or technicians should handle installation, maintenance, and repairs involving electric motors.

- De-Energization and Lockout/Tagout: Before performing any work on electric motors, they should be de-energized, and appropriate lockout/tagout procedures should be followed. This involves isolating the motor from the power source, ensuring that it cannot be energized accidentally. Lockout/tagout procedures help prevent unexpected startup and protect workers from electrical hazards.

- Personal Protective Equipment (PPE): When working with electric motors, appropriate personal protective equipment should be worn. This may include insulated gloves, safety glasses, protective clothing, and footwear with electrical insulation. PPE helps protect against potential electrical shocks, burns, and other physical hazards.

- Inspection and Maintenance: Regular inspection and maintenance of electric motors are essential to identify potential issues or defects that could compromise safety. This includes checking for loose connections, damaged insulation, worn-out components, or overheating. Any defects or abnormalities should be addressed promptly by qualified personnel.

- Proper Grounding: Electric motors should be properly grounded to prevent electrical shock hazards. Grounding ensures that any fault currents are redirected safely to the ground, reducing the risk of electric shock to individuals working on or around the motor.

- Avoiding Wet Conditions: Electric motors should not be operated or worked on in wet or damp conditions unless they are specifically designed for such environments. Water or moisture increases the risk of electrical shock. If working in wet conditions is necessary, appropriate safety measures and equipment, such as waterproof PPE, should be used.

- Safe Electrical Connections: When connecting or disconnecting electric motors, proper electrical connections should be made. This includes ensuring that power is completely switched off, using appropriate tools and techniques for making connections, and tightening electrical terminals securely. Loose or faulty connections can lead to electrical hazards, overheating, or equipment failure.

- Awareness of Capacitors: Some electric motors contain capacitors that store electrical energy even when the motor is de-energized. These capacitors can discharge unexpectedly and cause electric shock. Therefore, it is important to discharge capacitors safely before working on the motor and to be cautious of potential residual energy even after de-energization.

- Training and Knowledge: Individuals working with electric motors should receive proper training and have a good understanding of electrical safety practices and procedures. They should be knowledgeable about the potential hazards associated with electric motors and know how to respond to emergencies, such as electrical shocks or fires.

- Adherence to Regulations and Standards: Safety precautions should align with relevant regulations, codes, and standards specific to electrical work and motor operation. These may include local electrical codes, occupational safety guidelines, and industry-specific standards. Compliance with these regulations helps ensure a safe working environment.

It is crucial to prioritize safety when working with electric motors. Following these safety precautions, along with any additional guidelines provided by equipment manufacturers or local regulations, helps minimize the risk of electrical accidents, injuries, and property damage. Regular training, awareness, and a safety-focused mindset contribute to a safer working environment when dealing with electric motors.

What industries and applications commonly use electric motors?

Electric motors are widely utilized in various industries and applications due to their versatility, efficiency, and controllability. Here’s a detailed overview of the industries and applications where electric motors are commonly employed:

- Industrial Manufacturing: Electric motors are extensively used in industrial manufacturing processes. They power machinery and equipment such as conveyor systems, pumps, compressors, fans, mixers, robots, and assembly line equipment. Electric motors provide efficient and precise control over motion, making them essential for mass production and automation.

- Transportation: Electric motors play a crucial role in the transportation sector. They are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to drive the wheels, providing propulsion. Electric motors offer benefits such as high torque at low speeds, regenerative braking, and improved energy efficiency. They are also employed in trains, trams, ships, and aircraft for various propulsion and auxiliary systems.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize electric motors for air circulation, fans, blowers, and pumps. Electric motors help in maintaining comfortable indoor environments and ensure efficient cooling, heating, and ventilation in residential, commercial, and industrial buildings.

- Appliances and Household Devices: Electric motors are found in numerous household appliances and devices. They power refrigerators, washing machines, dryers, dishwashers, vacuum cleaners, blenders, food processors, air conditioners, ceiling fans, and many other appliances. Electric motors enable the necessary mechanical actions for these devices to function effectively.

- Renewable Energy: Electric motors are integral components of renewable energy systems. They are used in wind turbines to convert wind energy into electrical energy. Electric motors are also employed in solar tracking systems to orient solar panels towards the sun for optimal energy capture. Additionally, electric motors are utilized in hydroelectric power plants for controlling water flow and generating electricity.

- Medical Equipment: Electric motors are crucial in various medical devices and equipment. They power surgical tools, pumps for drug delivery and fluid management, diagnostic equipment, dental drills, patient lifts, wheelchair propulsion, and many other medical devices. Electric motors provide the necessary precision, control, and reliability required in healthcare settings.

- Robotics and Automation: Electric motors are extensively used in robotics and automation applications. They drive the joints and actuators of robots, enabling precise and controlled movement. Electric motors are also employed in automated systems for material handling, assembly, packaging, and quality control in industries such as automotive manufacturing, electronics, and logistics.

- Aerospace and Defense: Electric motors have significant applications in the aerospace and defense sectors. They are used in aircraft for propulsion, control surfaces, landing gear, and auxiliary systems. Electric motors are also employed in military equipment, drones, satellites, guided missiles, and underwater vehicles.

These are just a few examples of the industries and applications where electric motors are commonly used. Electric motors provide a reliable, efficient, and controllable means of converting electrical energy into mechanical energy, making them essential components in numerous technologies and systems across various sectors.

editor by CX 2023-10-20

China OEM AC/DC Motor Universal Motor 6830 with Pure Copper for Juicer/Grinder/Blender/Coffee Maker with Best Sales

Product Description

Specialist Maker OF Single-Phase Collection MOTOR /Gear MOTOR

Electrical power,Pace,Torque,Shaft ,Stator Lamination,Rotation And Putting in Spot

can be tailored according to consumer‘s requirements.

Product Description:

| Product Name: | AC Single phase series motor |

| Model No. : | XJ68-thirty |

| Model: | HangZhouA |

| Application: | For Juicer/Food Processor/Food Mixer/Blender |

| Starting Mode | Direct on-line Starting |

| Rated Voltage: | 100V 110V 120V 127V 220V 230V 240V |

| No-load Power: | fifty-150W |

| No-load Speed: | 13000-32000rpm |

| Load Power: | 100-300W |

| Load Speed: | 8000-19000rpm |

| Rotation Direction: | CW/CCW |

| Rating Frequency: | fifty/60 Hz |

| Insulation Class: | A/E/B/F |

| Protection Grade: | IP00 ~ IP68 |

| Packing: | foam&carton,or accroding to customers’ specific requirements |

| MOQ: | 500 pcs |

| Delivery Time: | Depends on quantity from 2 weeks to 4 weeks. |

| Payment Term: | T/T, L/C, D/P |

Remarks:

- The performances as above are just for reference only. We can alter our motor specifications in accordance to customer’s demands.

- OEM & ODM are equally obtainable. You should truly feel free of charge to get in touch with us with your detailed needs .

- If question for quotation, make sure you tell voltage, draft, input power, air circulation at the very least, so we could estimate quickly.

Depth Look at:

Second-Drawning:

Short Introduction

HangZhou Xihu (West Lake) Dis. HangZhoua Electric powered Equipment Factory was established in 1997, it is found in Xihu (West Lake) Dis. District of HangZhou, ZHangZhoug Province.We have about fifty,000 square meters of the developing and virtually 300 personnel. In addition, the transportation all around the factory is extremely handy, it is close to the TongSan Highway, and is just 8 kilometers absent from the HangZhou Airport.

By way of several years of accumulation and improvement, our manufacturing facility is now a skilled manufacturer of one-section series motor and gear reducer motor.The application of our merchandise handles many fields,it is mainly utilized in home kitchen area appliances or electric powered equipment, this sort of as juicer, ice crusher, meat grinder, espresso bean grinder , lawn mower and so on.

Our manufacturing unit has superior common motor manufacturing line, sturdy complex power, excellent tests means, merchandise can be created according to worldwide and domestic expectations, but also according to customer needs or provided samples, drawings and other unique design.Our function sticks to the principle of striving for existence by fine quality. Our merchandise sell much all over the entire world.Our factory will, and as always, wholeheartedly serves broad aged and new buyers each at home and overseas. We are seeking forward to establishing company interactions with buyers all above the entire world.

FAQ:

Q1: Are you a trade organization or a maker?

A1: HangZhou Xihu (West Lake) Dis. HangZhoua Motor Manufactory was proven in 1997, we are a professional

manufacturer of solitary-period collection motor and equipment motor.

Qtwo: How about sample and charge?

A2: Our sample policy stipulates that buyers must shell out for sample and express payment,but we could

return the sample and express payment based mostly on specific purchase quantity. You can specify the convey business you want that like DHL, or you can phone your courier to select up from our manufacturing unit.

Q3: What is your payment terms?

A3: one. We settle for T/T, D/P, L/C at sight.

2. thirty% deposit in CZPT and 70% harmony prior to cargo.(Sum far more than 3000USD)

Qfour: How can we get thorough price tag?

Afour: Remember to offer us detailed information of the product,distinct packaging requirements and getting

quantity.

Qfive: Is it achievable to visit your manufacturing unit

A5: Confident. But you should kindly preserve us posted a couple of days in progress. We require to check out our schedule to see if we are available then.

Qsix: How to assure punctual cargo for my buy?

A6: We give precedence to export orders and hold updating development from production to shipping.

Q7: What about the following-product sales services?

Aseven: Via e-mails, photographs or visitor samples to confirm the genuine trigger of the difficulty. If there is truly

a product dilemma, we will redo with no charge.

Q8: What is your shipping and delivery day?

A8: The supply date is about twenty-30 days after obtaining your deposit,it relies upon on the amount you

order.

Induction motors, also acknowledged as asynchronous motors, use the electromagnetic induction produced by the magnetic field of the stator to produce existing in the rotor, thereby producing torque. These motors do not run at a velocity in sync with the present, that’s why the identify. They use the phenomenon of electromagnetic induction to change electrical vitality into mechanical strength. Induction motor rotors are the most common type of AC motor identified in pumps, compressors, and other machines of all varieties.

Synchronous motors run at a pace that is synchronous with the frequency of the mains present. This signifies that in the constant-state of the motor, the rotation of the shaft is synchronized with the frequency of the offer present. The period of rotation of the shaft is equal to the amount of AC cycles. The stator of a synchronous motor has polyphase AC electromagnets. These electromagnets create a magnetic field that rotates in synchrony with the current in the wire. The rotor equipped with long lasting magnets or electromagnets rotates synchronously with the stator magnetic subject to sort the second synchronous rotating magnetic field of the AC motor.

China Professional Customized High Speed Electric Mixers with Carbon Brush Universal Motor with Hot selling

Product Description

100W Electrical AC Universal Motor for House Appliance

Product characteristic

1. Stator measurement is optional

two. Risk-free, trustworthy, reduced sound, very good starting, long daily life

three. Powerful power

Rated voltage 110~120V/220~240V-50/60Hz

Typical used:

Exhaust enthusiast, air purifier, micro-oven, enthusiast, induction cooker, fridge, pump, heater, hood oven, blwer, air conditioner, Heater devices, dehumidifiers

Thermal protector with 1 shot fuse or multi shot fuse

Hair dryer universal motor:

one. Rated: 100-240V, fifty/60Hz

2. Rated velocity: 6000-22000rpm

3. Enter Electrical power: 100-700W

4. Insulation class: A B F H

Rated voltage a hundred~240V-50/60Hz

Typical used: Exhaust supporter, air purifier, micro-oven, supporter, induction cooker, refrigerator, pump, heater, hood oven, blwer, air conditioner, Heater machines, dehumidifiers

AC motors are also different from DC motors simply because most AC motors do not include brushes. This signifies that upkeep and areas replacement needs for AC motors are likely to be substantially decreased, with most users typically expecting a lengthier regular lifespan. As opposed to DC motors, the output velocity of numerous varieties of AC motors is usually determined by inverter control – yet again, we’ll briefly outline a selection of potential versions on the standard AC motor product.

These NEMA c-aircraft reducers are gear power, upkeep-cost-free, and can be put in in any orientation with a slip fit “O” ring style. Available in reduced to high reduction ratios, flange mount or foundation mount designs, appropriate angle or hollow shaft proper angle variations. Set up NEMA C-Experience AC motors, brushless DC motors, and brushed DC motors. For 1/2 HP to 3 HP Motors NEMA 56C, 140TC, and 180TC Enter Flange Inline Helical Equipment Reducers Correct Angle Hypoid Gear Reducers

China Custom 95 AC Auto Parts Universal High Power Electric Electrical Hub Fan Motor for Blender/Juicer/Meat Grinder/Massage Chair/Mixer/Ice Crusher Maker/Lawn Monwer Home a with Great quality

Merchandise Description

9535 Common Motor

Voltage:a hundred and ten-220VAC

Power:1200-1500w

Present:5-6.5A

Pace:29000RPM+/-15%

Torque:20NM

Isulation Class:B/F

Stand up to Voltage: 1800V/1Sec/3mA (QA Take a look at: 1500V/60Sec/5mA

Themal fuse:One particular shot/recoverable

one.Application:The AC motor is commonly employed for blender, electrical sharpener, electric kinfe, foods processor, electrical switching and other

kitchen appliances and so on.

2.Our motors efficiency(info) are for each customers` requirments.

3.Motor wires are cooper and some could be employed aluminium wire to preserve price

four.Motors could be used ball bearing and oil bear(Sleeve bearing) equally.

5.Stators could be chilly metal and silicon steel

six.We can use equally one particular-shot thermal fuse and recoverable thermal fuse

7.Our AC motors are of higher efficiency, exceptional high quality, minimal strength usage, long life and aggressive cost.

eight.The top quality of every single AC blender motor is a hundred% inspected prior to packing.

| Design |

Voltage(VAC) | Electricity(W) | Present(A) | Toruque(NM) | Velocity(RPM) | Measurement(mm) |

| 9535 |

110-220 | 1200-1500W | 5-6.5 | twenty | 29000 | 152*one hundred thirty*sixty five |

Fine Watt motor target on giving motor solutions to smart merchandise for house equipment ,like BLDC,Capacitor motor,shaded pole motor,common motor and mini generator. Our motors are broadly utilised in kitchen area,air conditional,Ice upper body,washing machine,and so on. Consumers track down not only in China domestic ,also oversea from Asia to European and Amecica. Our engineer with 20 a long time expertise in motor layout and improvement,win a great deal of motor inovation technological innovation award,Our engineer also supply complex help to other big facotry.we think we always can discover the greatest resolution for your item.

Organization FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we primarily give Kitchen Hood Motor,DC Motor,Gear Motor,Supporter Motor Fridge Motor,Hair Dryer Motor Blender Motor Mixer Motor,

BLDC Motor,Shade Pole Motor,Capacitor Motor, PMDC Motor,Synchronous Motor,and so on

(2) Q: Is it attainable to check out your manufacturing unit

A: Positive. We usually like to fulfill our buyer encounter to encounter,this is better for knowing.But you should kindly maintain us posted a few days in CZPT so we can make very good arrangement.

(3) Q: Can I get some samples

A: It is dependent. If only a handful of samples for private use or substitution, I am scared it will be difficult for us to supply, simply because all of our motors are personalized created and no stock available if there is no more needs. If just sample screening ahead of the formal order and our MOQ, price tag and other conditions are acceptable, we will offer samples.

(4) Q: Is there a MOQ for your motors?

A: Sure. The MOQ is between one thousand~ten,000pcs for diverse types following sample acceptance.

But it truly is also okay for us to acknowledge smaller tons like a few dozens, hundreds or 1000’s

For the preliminary 3 orders right after sample acceptance.For samples, there is no MOQ prerequisite. But the much less the much better (like no far more than 5pcs) on problem that the quantity is adequate in case any changes essential right after original screening.

(5)Q: What gain do you have?

A: For motors, we have quality guarantee, if there is probelm motor soon after inspection in client property,we will replace .

For provider, we offer you 24 hrs specialized assistance and barrier-free communication with outstanding service men and women.

Complex provider: Except offer you genuine motor items,we can also offer motor specialized supporting seperately to our consumer.Our engineers are represent the most advanced techonogy.

An AC motor is a variety of motor that makes use of the phenomenon of electromagnetic induction. AC power drives the motor. It is a recent that periodically reverses route and alterations its magnitude of the existing above time. This existing is the opposite of a immediate existing or “DC” which flows in only one path. AC motors can provide a comparatively effective way to create mechanical strength from a easy electrical enter signal.

AC motors vary from several other varieties of motors, especially some of the much more common DC (immediate existing) motors, by several important criteria. The most standard of these is the fact that an AC motor depends totally on the alternating existing about its circuit to create successful mechanical power. We will talk about this distinctive method in a lot more depth in the adhering to sections of this guidebook.

China Standard MCBV Series low noise Single-phase capacitor electrical motor Universal Motor with Free Design Custom

Item Description

Product Description

Basic Description

Single-section capacitive electrical motor only needs single-stage power offer, Which has the benefits of basic construction, low value and low sound. For that reason, it is extensively utilized in some modest energy products of family appliances and medical devices such as electric powered enthusiasts, refrigerators, vacuum cleaners and air conditioners In the market place, this kind of motor variety and amount are more

Merchandise Parameters

Squirrel Cage Motor Technological Information

Firm Profile

one.You need to spend for samples and the freight will be borne by the buyer.

two.PaymentmethodT/T,L/C.

three.Delivery:Bysea, samples can be transported by air.

4.Under standard circumstances, it will be transported 1 month soon after the purchase is placed.

five.We can supply OEM,ODM.

six.Massive batches of goods are packed in cartons and can be tailored according to clients.

seven.The unique motor can be personalized according to the customer’s sample, and the certain value is talked about.

Induction motors, also acknowledged as asynchronous motors, use the electromagnetic induction produced by the magnetic subject of the stator to generate existing in the rotor, therefore making torque. These motors do not operate at a pace in sync with the recent, therefore the title. They use the phenomenon of electromagnetic induction to transform electrical energy into mechanical energy. Induction motor rotors are the most typical kind of AC motor located in pumps, compressors, and other machines of all varieties.

Synchronous motors operate at a pace that is synchronous with the frequency of the mains current. This means that in the continual-state of the motor, the rotation of the shaft is synchronized with the frequency of the supply current. The period of time of rotation of the shaft is equivalent to the amount of AC cycles. The stator of a synchronous motor has polyphase AC electromagnets. These electromagnets produce a magnetic discipline that rotates in synchrony with the existing in the wire. The rotor geared up with long lasting magnets or electromagnets rotates synchronously with the stator magnetic discipline to sort the second synchronous rotating magnetic subject of the AC motor.

China supplier AC Motor Electrical Motor Electric Engine Universal Motor 9435 Shaft Customized with Aluminum Bracket for High Speed Blender with Free Design Custom

Item Description

Skilled Maker OF One-Section Collection MOTOR /Equipment MOTOR

Electricity,Pace,Torque,Shaft ,Stator Lamination,Rotation And Setting up Area

can be customized according to customer‘s requirements.

Product Description:

| Product Name: | AC Electrical Motor/Universal Motor |

| Model No.: | XJ9435 |

| Brand: | HangZhouA |

| Application: | for High Speed Blender/Mixer/Grinder/Juicer |

| Starting Mode | Direct on-line Starting |

| Rated Voltage: | one hundred/a hundred and ten/120/127/220/230/240 V |

| Rated Frequency: | fifty/60 Hz |

| No-load Power: | two hundred-400W |

| No-load Speed: | 13000-35000rpm |

| Load Power: | 500-900W |

| Load Speed: | 8000-18000rpm |

| Rotation Direction: | CW/CCW |

| Insulation Class: | A/E/B/F |

| Protection Grade: | IP00 ~ IP68 |

| Packing: | foam&carton,or accroding to customers’ specific requirements |

| MOQ: | 500 pcs |

| Delivery Time: | Depends on quantity from 2 weeks to 4 weeks. |

| Payment Term: | T/T, L/C, D/P |

Remarks:

- The performances as above are just for reference only. We can modify our motor technical specs according to customer’s requirements.

- OEM & ODM are equally obtainable. Make sure you feel free of charge to contact us with your thorough requirements .

- If request for quotation, make sure you inform voltage, draft, input power, air movement at least, so we could estimate rapidly.

Depth Look at:

2d-Drawning

Short Introduction

HangZhou Xihu (West Lake) Dis. HangZhoua Electric powered Equipment Factory was established in 1997, it is situated in Xihu (West Lake) Dis. District of HangZhou, ZHangZhoug Province.We have about fifty,000 sq. meters of the creating and practically three hundred personnel. In addition, the transportation close to the factory is very convenient, it is near to the TongSan Freeway, and is just 8 kilometers absent from the HangZhou Airport.

By way of a long time of accumulation and growth, our manufacturing unit is now a skilled maker of single-period series motor and gear reducer motor.The software of our merchandise covers a lot of fields,it is mainly used in house kitchen area appliances or electric powered tools, this sort of as juicer, ice crusher, meat grinder, espresso bean grinder , garden mower and so on.

Our manufacturing unit has superior universal motor creation line, powerful complex force, perfect testing indicates, items can be produced according to global and domestic expectations, but also according to customer needs or provided samples, drawings and other special design and style.Our function sticks to the theory of striving for existence by fine top quality. Our items market far all over the entire world.Our manufacturing facility will, and as constantly, wholeheartedly serves broad previous and new consumers each at residence and abroad. We are hunting ahead to developing organization relationships with customers all over the world.

FAQ:

Q1: Are you a trade business or a producer?

A1: HangZhou Xihu (West Lake) Dis. HangZhoua Motor Manufactory was established in 1997, we are a professional

manufacturer of solitary-stage series motor and gear motor.

Qtwo: How about sample and charge?

A2: Our sample policy stipulates that consumers need to pay out for sample and categorical price,but we could

return the sample and express charge based on certain order quantity. You can specify the convey firm you want that like DHL, or you can contact your courier to choose up from our factory.

Q3: What is your payment conditions?

Athree: 1. We acknowledge T/T, D/P, L/C at sight.

2. 30% deposit in CZPT and 70% harmony before shipment.(Amount more than 3000USD)

Qfour: How can we get in depth price tag?

A4: Make sure you offer us detailed data of the merchandise,certain packaging requirements and buying

quantity.

Q5: Is it feasible to visit your manufacturing facility

A5: Confident. But make sure you kindly hold us posted a couple of days in advance. We require to verify our schedule to see if we are available then.

Q6: How to promise punctual shipment for my get?

A6: We give precedence to export orders and preserve updating progress from generation to delivery.

Qseven: What about the after-sales service?

Aseven: Through email messages, photos or visitor samples to validate the true lead to of the problem. If there is truly

a product issue, we will redo with no demand.

Q8: What is your delivery day?

A8: The delivery date is about 20-30 days after acquiring your deposit,it depends on the amount you

order.

Induction motors, also acknowledged as asynchronous motors, use the electromagnetic induction produced by the magnetic discipline of the stator to produce recent in the rotor, therefore creating torque. These motors do not operate at a speed in sync with the current, that’s why the title. They use the phenomenon of electromagnetic induction to transform electrical vitality into mechanical strength. Induction motor rotors are the most common type of AC motor identified in pumps, compressors, and other machines of all kinds.

An AC motor is a kind of motor that utilizes the phenomenon of electromagnetic induction. AC electrical power drives the motor. It is a recent that periodically reverses course and modifications its magnitude of the present in excess of time. This recent is the reverse of a immediate current or “DC” which flows in only one route. AC motors can offer a fairly productive way to make mechanical strength from a easy electrical input signal.